Frequently Asked Questions (FAQ)

How can we assist you?

Mexx Engineering® will assist in evaluating the customer's readiness for an automated system. The next step is identifying which automation system best suits the operational needs of the customer. With many integration options available, Mexx Engineering® will develop and manufacture the best system that fits the customer’s application.

A standard project timeline consists of:

- An enquiry is being received

- Follow up call is made to identify customer’s specifications

- A 2D concept and quote are presented to the customer

- Payment options are discussed

- Contract signing between the customer and Mexx Engineering®

- Detailed designing phase

- Prototyping phase

- Initial building phase at the Mexx Engineering® facility

- Testing phase at the Mexx Engineering® facility

- Delivery and commissioning of the system at the customer's facility

Mexx Engineering® recognises that the performance of its team members is pivotal to meeting and exceeding its customers’ requirements in developing and manufacturing automated robotic systems.

Our customers can assure the future growth of their respective businesses and become partners in success by working collaboratively according to the requirements and expectations outlined in our Quality Management System.

A successful partnership requires both parties to work together with a strong level of commitment to ensure the delivery of quality products and services.

We are committed to improve productivity, mitigate risks and hazards, reduce energy use, and cut waste generation within the manufacturing industry.

What are the benefits of automated systems?

Many companies are investing in automated systems because it conserves money, time and resources. It also increases productivity and product quality. Robots handle tasks with precision and accuracy, making fewer mistakes. It can perform repetitive tasks 24 hours a day. There are fewer accidents because most of the risks and hazards are avoided, and waste is effectively reduced. Therefore, making the production floor safer for human interaction.

Will automation reduce my operating costs?

Yes, it can. Using an automated system can reduce both direct costs and overheads. The cost-effectiveness of systems designed and developed by Mexx Engineering® can increase your competitiveness within the manufacturing industry.

Another way of reducing costs is by minimising imported packaging solutions. Within the food and beverage industry, the manufacturer can effectively cut out the cost of the international inbound freight by manufacturing their own plastic bottles. The ability to produce the same or greater quantities of plastic bottles here in Australia can decrease the manufacturing cost of their product per item, therefore making it more profitable.

If you'd like to know more simply, Contact Us

How long does it take to design and build an automated system?

As a stand-alone machine or OEM product, it may take around 25-weeks from purchase order to delivery. On the other hand, a custom-made turnkey system can take longer depending on the customer's requests and specifications.

Can automation improve product quality and consistency?

Yes, it sure can. With an automated system, you can produce a consistent and high-quality end product. The machines do not tire or get injured due to repetitive tasks. A fully automated system can perform tasks consistently 24/7.

What to learn more about how we can assist you in automating your manufacturing systems?

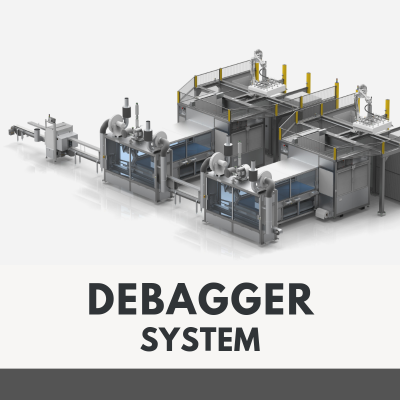

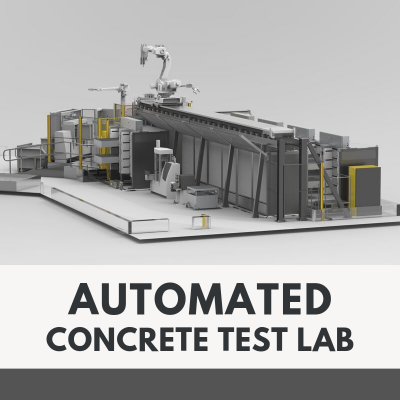

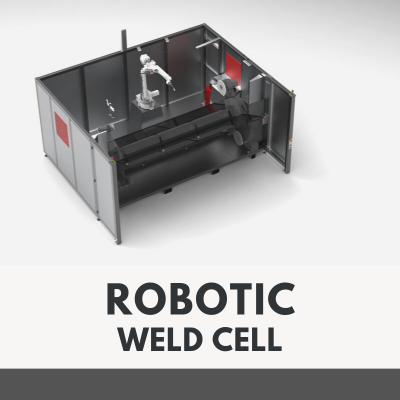

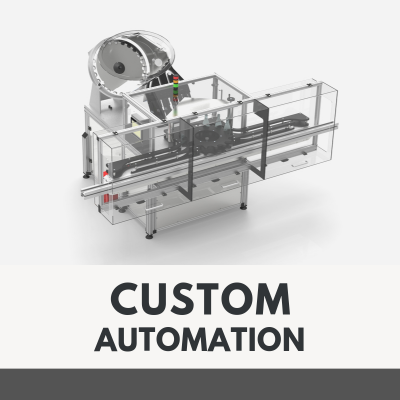

What are the various types of products and services we offer?

Are there any warranties offered?

Yes, of course. All of Mexx Engineering machines and turnkey systems come with a one-year warranty on workmanship and materials.

Do you offer any maintenance support after installation?

Definitely! After commissioning an automated system to our customers, we offer a semi-annual or yearly service maintenance agreement. Mexx Engineering will do all the necessary work to keep our machines in good repair and operating condition. It includes maintaining and repairing essential components of a machine.

This excludes any new work and alterations such as:

- manufacturing and modifying machines and complete lines

- providing decorative treatments

- modifying vision systems

- attaching or extending items to the machine.

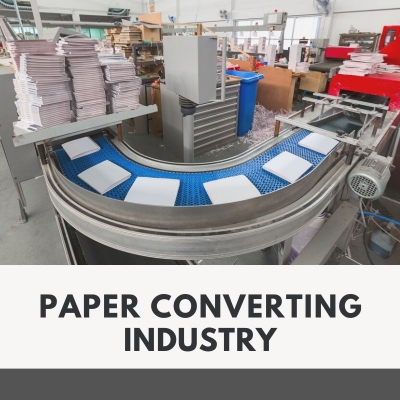

What are the different industries we cater to?

What are things to consider before investing in automated systems?

You should evaluate your company’s readiness before making the investment into an automated system. Look specifically at the technology itself, your current IT team and any “gaps” that might lie between the two, your team’s aptitude, in-house skill sets and familiarity with the technology. Once you have completed this self-assessment of your technical and cultural readiness, you will have a much better idea if your business is ready for an automated manufacturing facility.

Determining which automation system best suits your business is the next step. Mexx Engineering will assist in designing and building a sophisticated industrial automation system for your manufacturing line. With many integration options available, Mexx will ensure that we find the best process to establish which system fits your application, product, and financial needs.

How does system automation affect logistical operations?

Rather than viewing your new automated manufacture system as a stand-alone entity, consider how it works in concert with the rest of the supply chain and logistical operations. The automation of the supply chain from beginning to end allows the logistics supervisors to dedicate less time on individual, mundane processes, and more time on getting the most out of their supply chains. An automated system makes it possible for supply chain managers to enhance their operations. By investing in automation tools like robotics and automated warehouse management techniques that improve productivity, managers can create a significantly better bottom line in the long run.

Each system developed by Mexx Engineering® is a seamless automated machine that minimises environmental impact, and maximises performance while ensuring the safety of its operator.

For more information, please contact 07 5571 5733 and choose option 1 for sales, to discuss the best combination of equipment and system maintenance to suit your application.