Robotics, Automation & Custom Engineering – EPCM

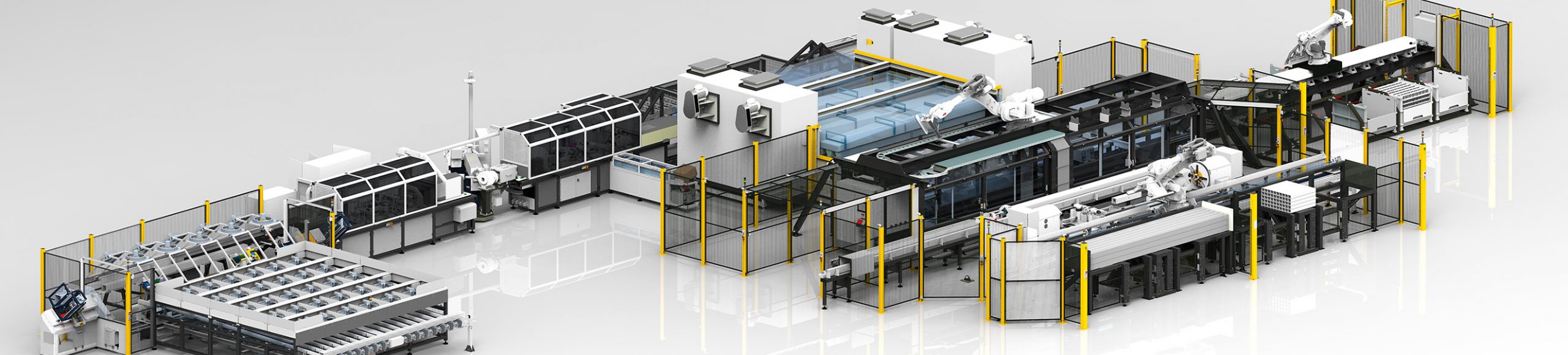

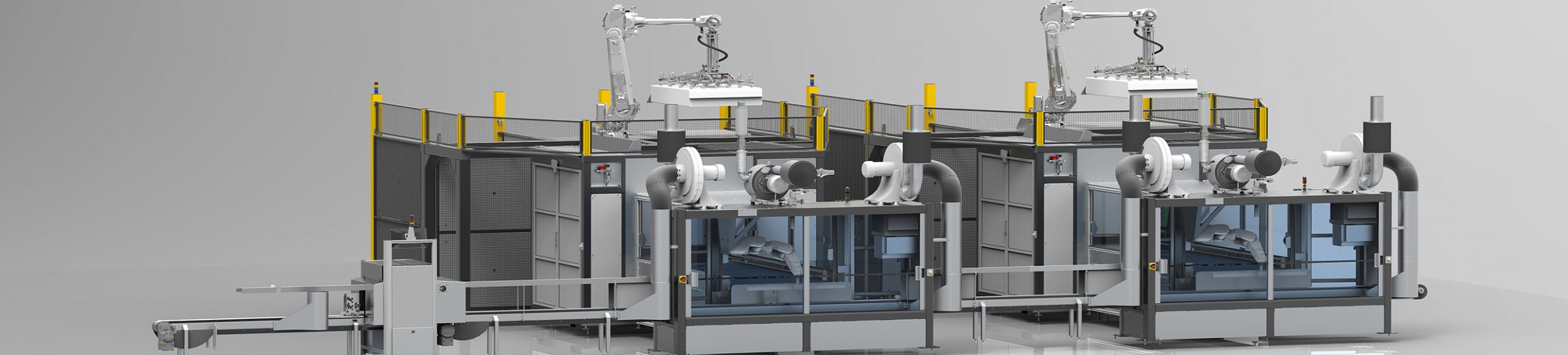

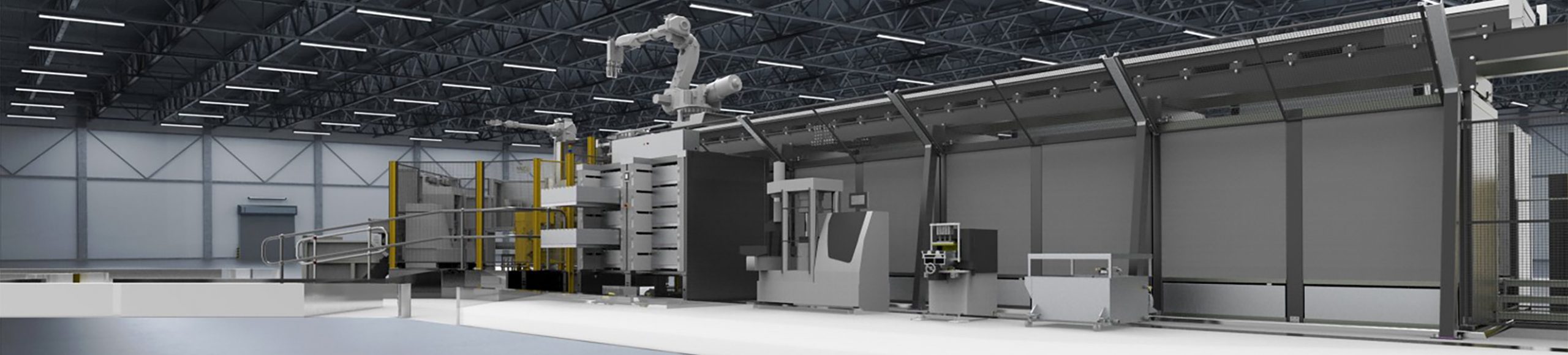

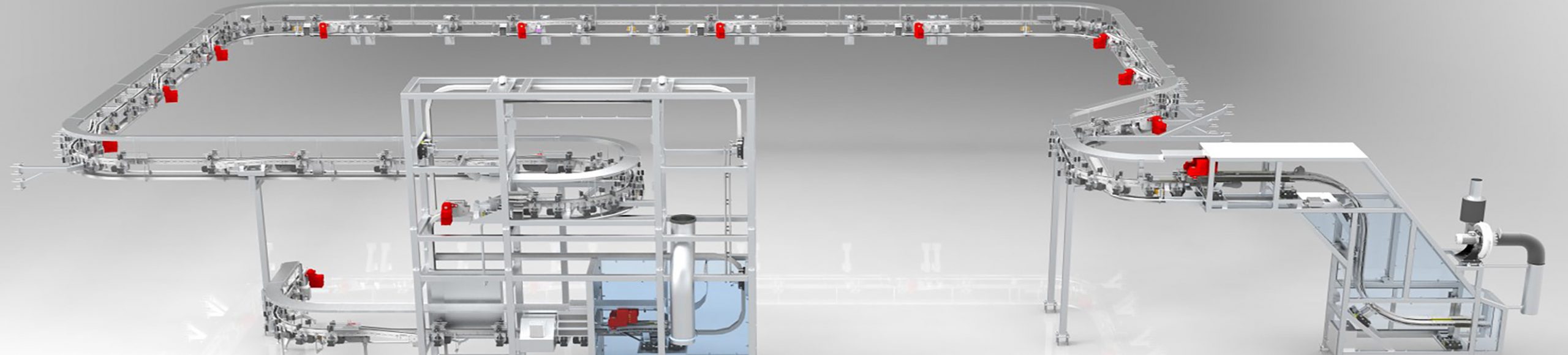

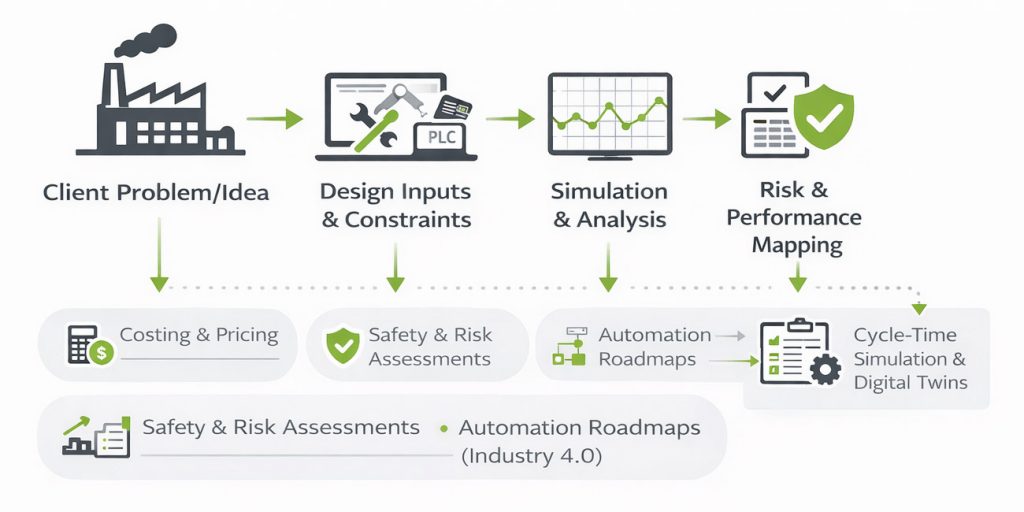

Before capital is committed to automation or robotics, Mexx defines system architecture, validates performance assumptions, and retires technical risk. Our engineering team integrates mechanical, mechatronic, process, controls, structural and electrical disciplines with digital twin modelling and simulation to convert complex operational challenges into defined, procurement-ready engineering pathways.

Pre-Feasibility & Feasibility

- Option development & constraint definition

- Throughput and performance modelling

- Safety and risk identification

FEED (Front End Engineering Design)

- Layout and integration strategy

- Mechanical, electrical and controls definition

- Capital cost band development

Digital Engineering & Validation

- Cycle-time simulation

- Digital twin development

- Automation architecture roadmapping

Robots, automation modules, control panels and industrial components.

Feasibility, design studies, risk, safety and engineering optimisation.

Robotics, automation systems, digital twins, SCADA/MES and engineering.

24/7 support, remote diagnostics, field technicians and maintenance.

Project Roadmap

i[email protected]

(07) 5571 5733

Unit2, 28 Harrington Street, Arundel. 4214, Australia