Marine

Manufacturers in the marine industry have come to expect the best performing robotic solutions available globally.

Mexx Engineering® is one of the few robotics and automation companies in Australia. We are known for designing and manufacturing complete lines that are built to handle a range of functions from upstream processing, sorting and packing through to the end of line palletisation.

Mexx Engineering® can streamline the marine industry using innovative and versatile systems such as:

The implementation of robotic automation within the marine industry offers incredible potential for improved safety, quality and productivity by enhancing process monitoring and control.

Robotic welding machines and spray booths are becoming more prominent themes in boat building, shipyards and the marine industry.

The shipping and marine industry continues to remain a labour-intensive sector, and now businesses are looking to amplify their use of robotics and automation technologies. This opportunity is where Mexx Engineering® can assist in providing a top-of-the-line solution to the shipbuilding industry.

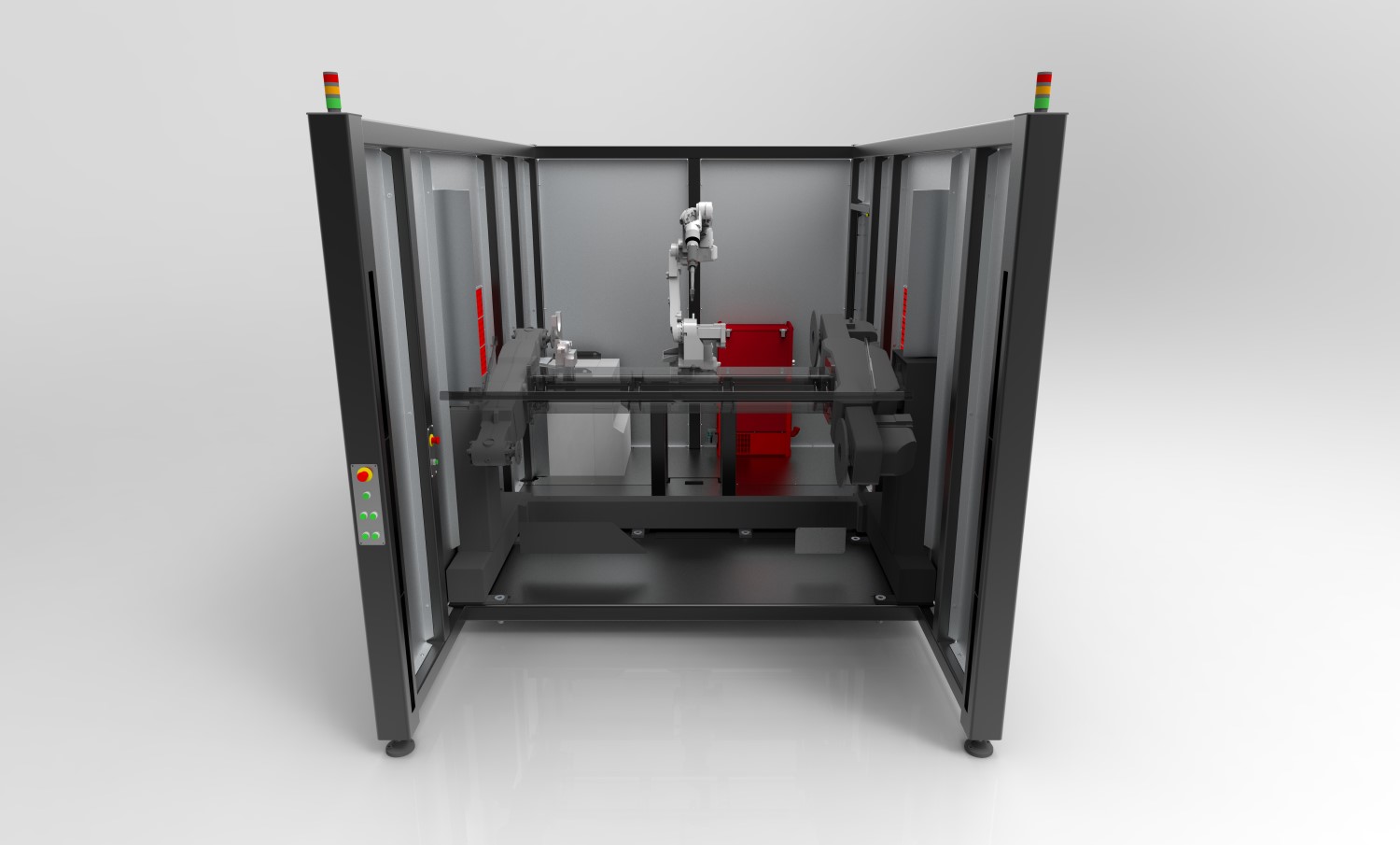

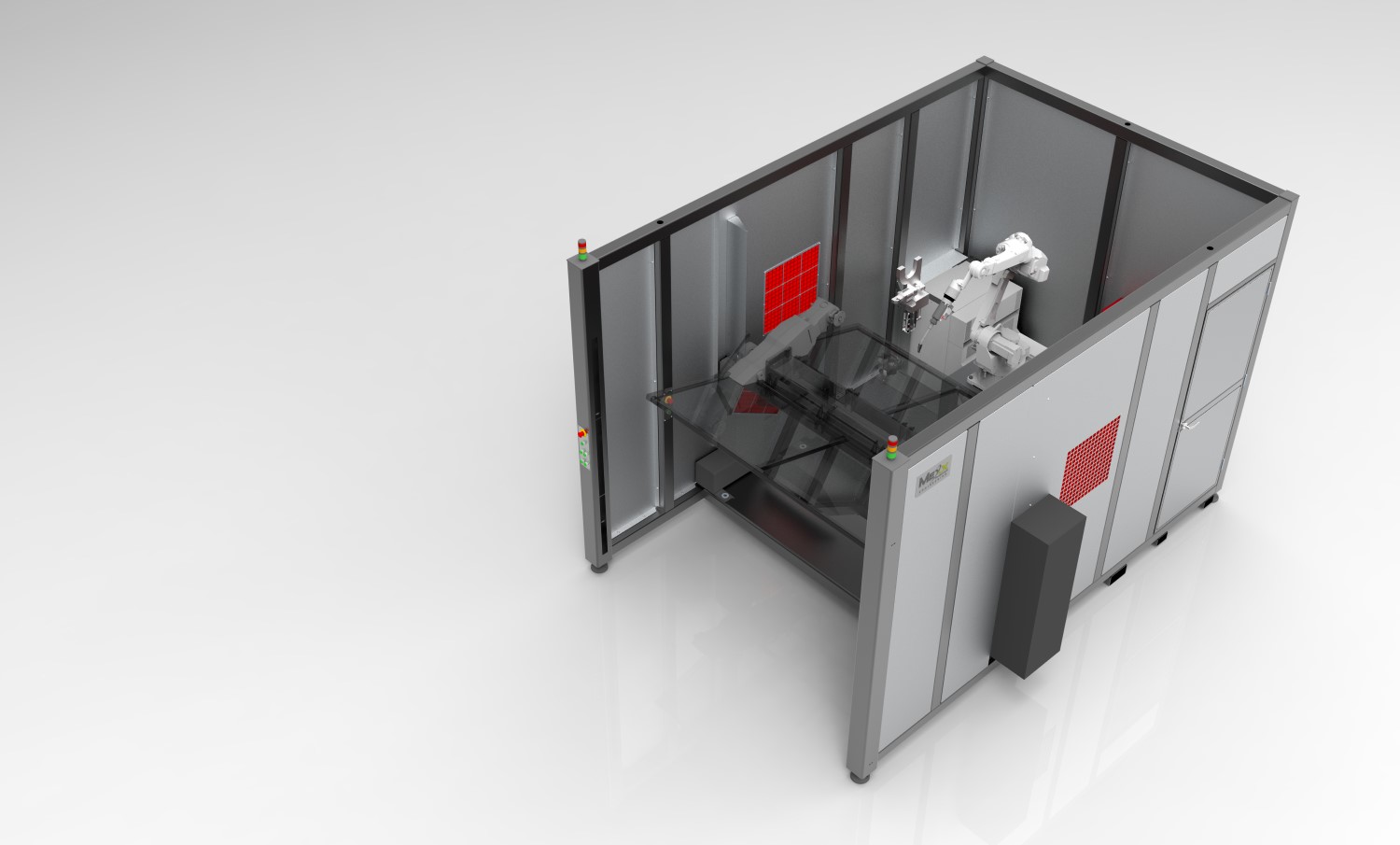

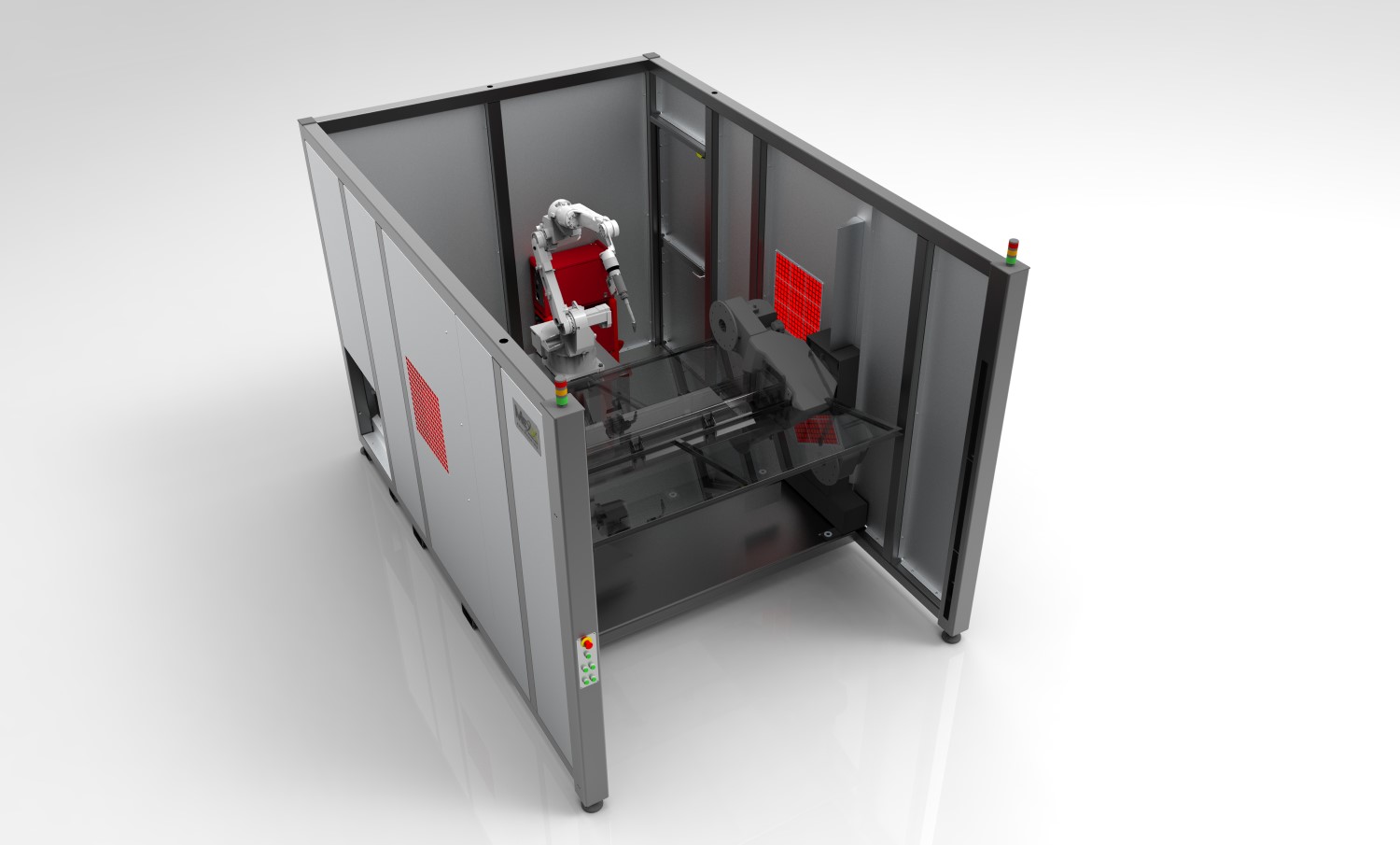

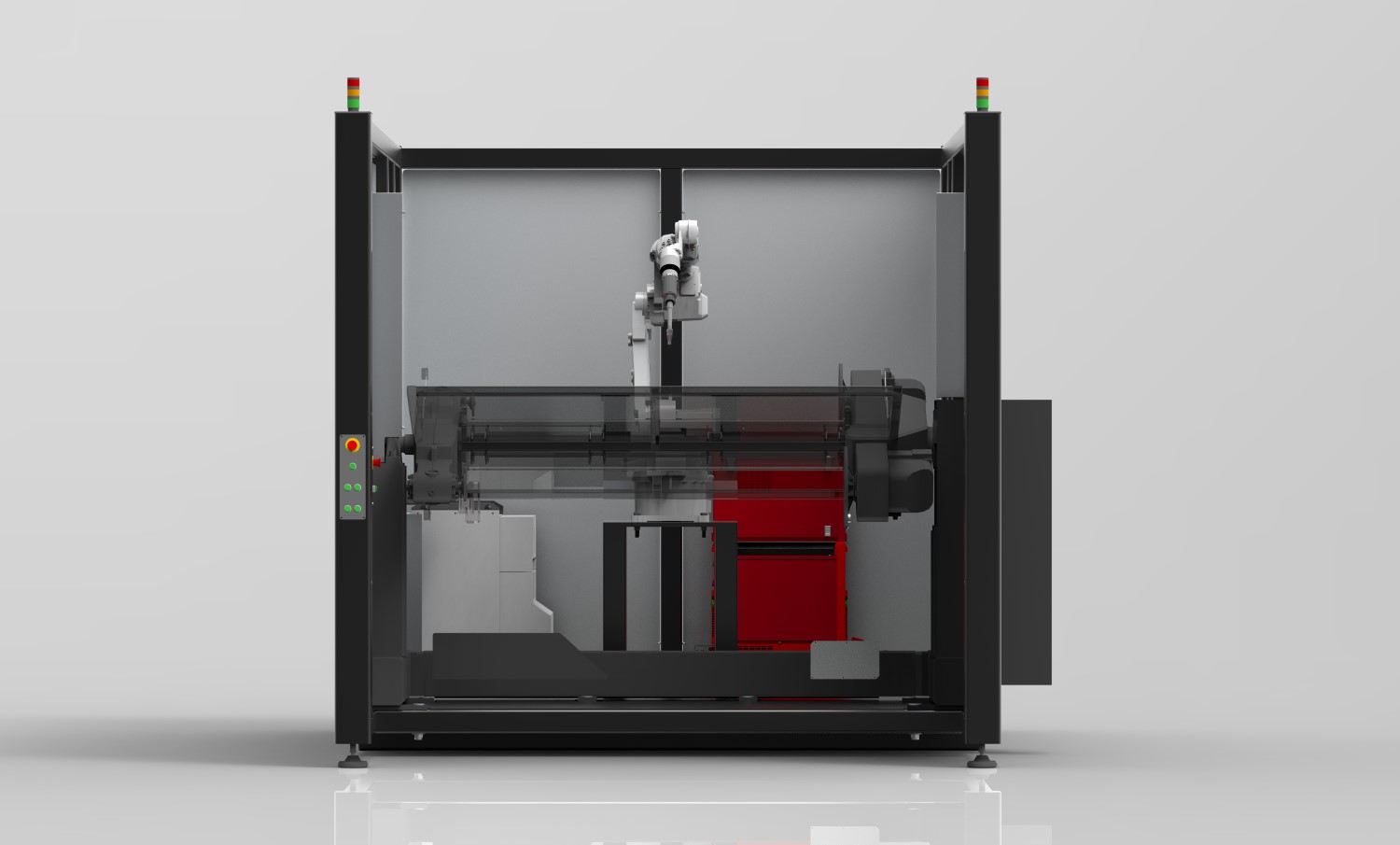

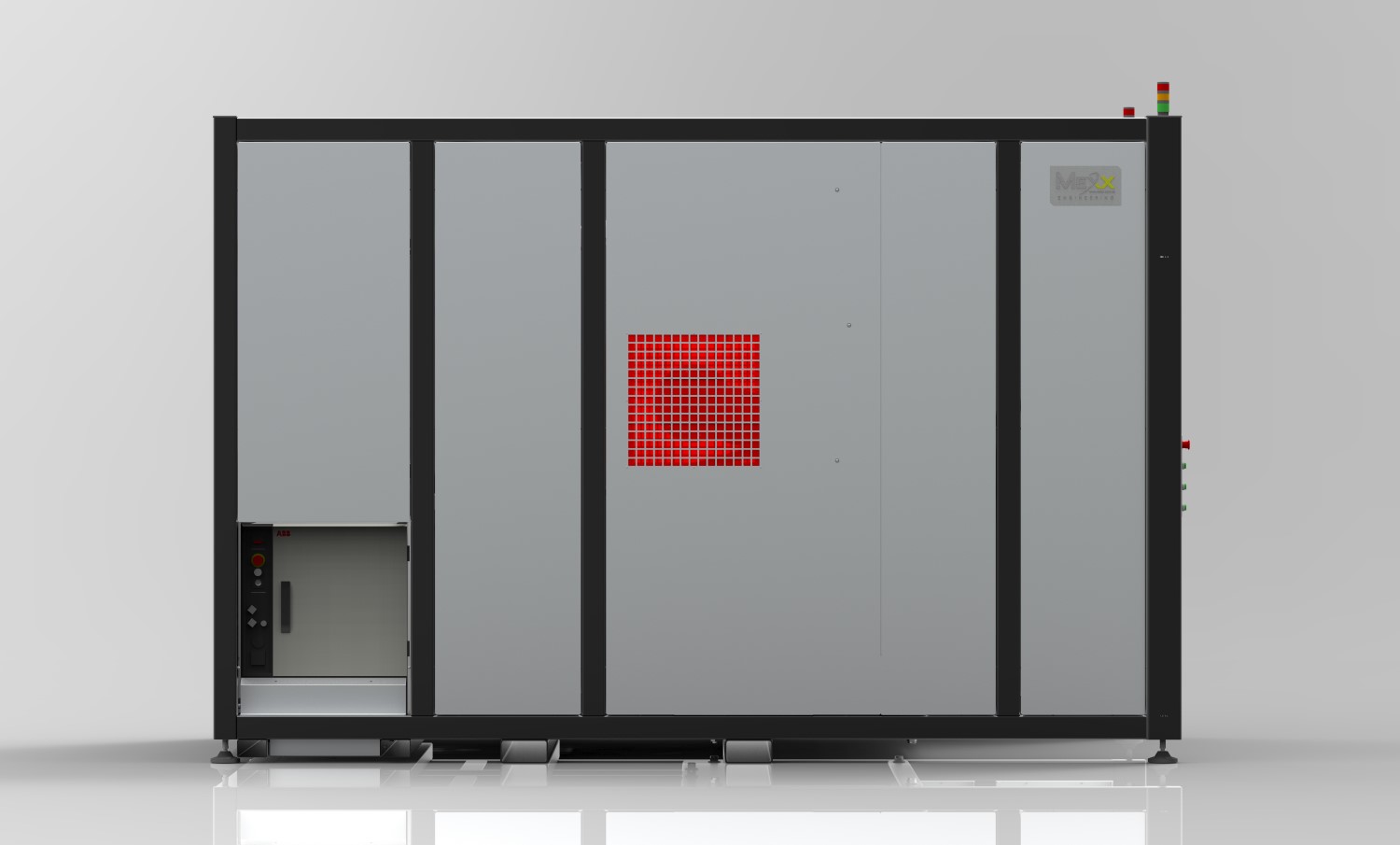

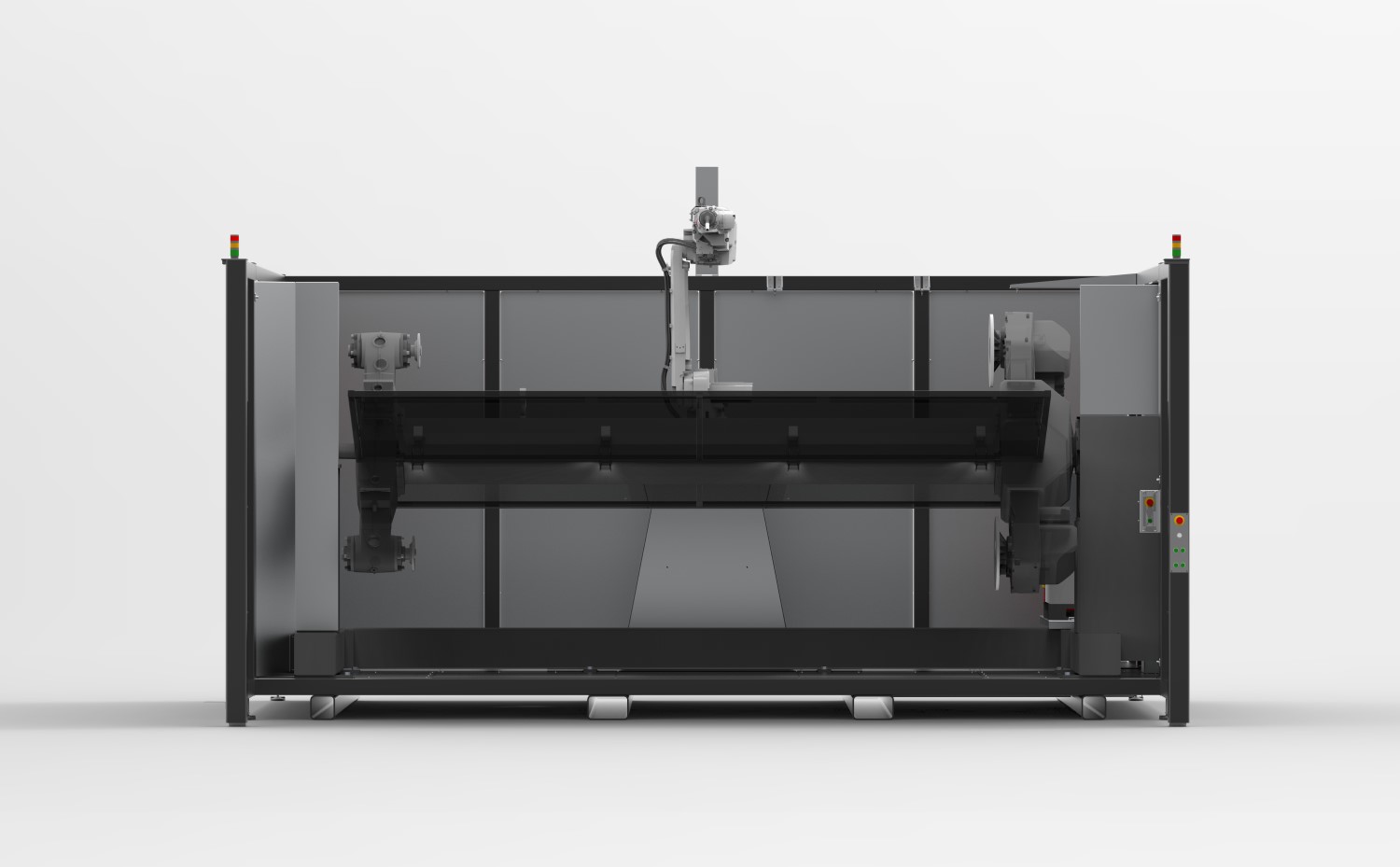

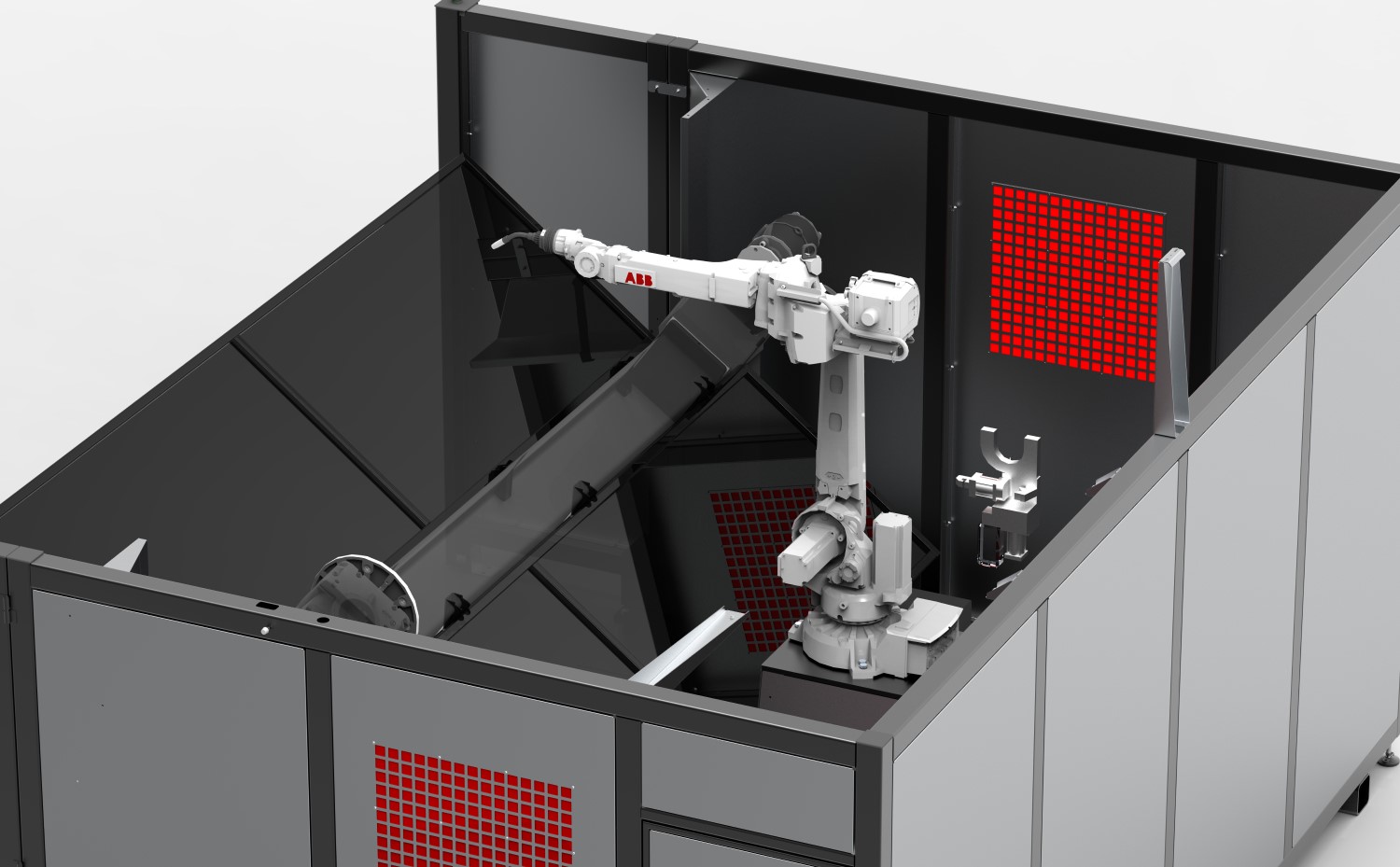

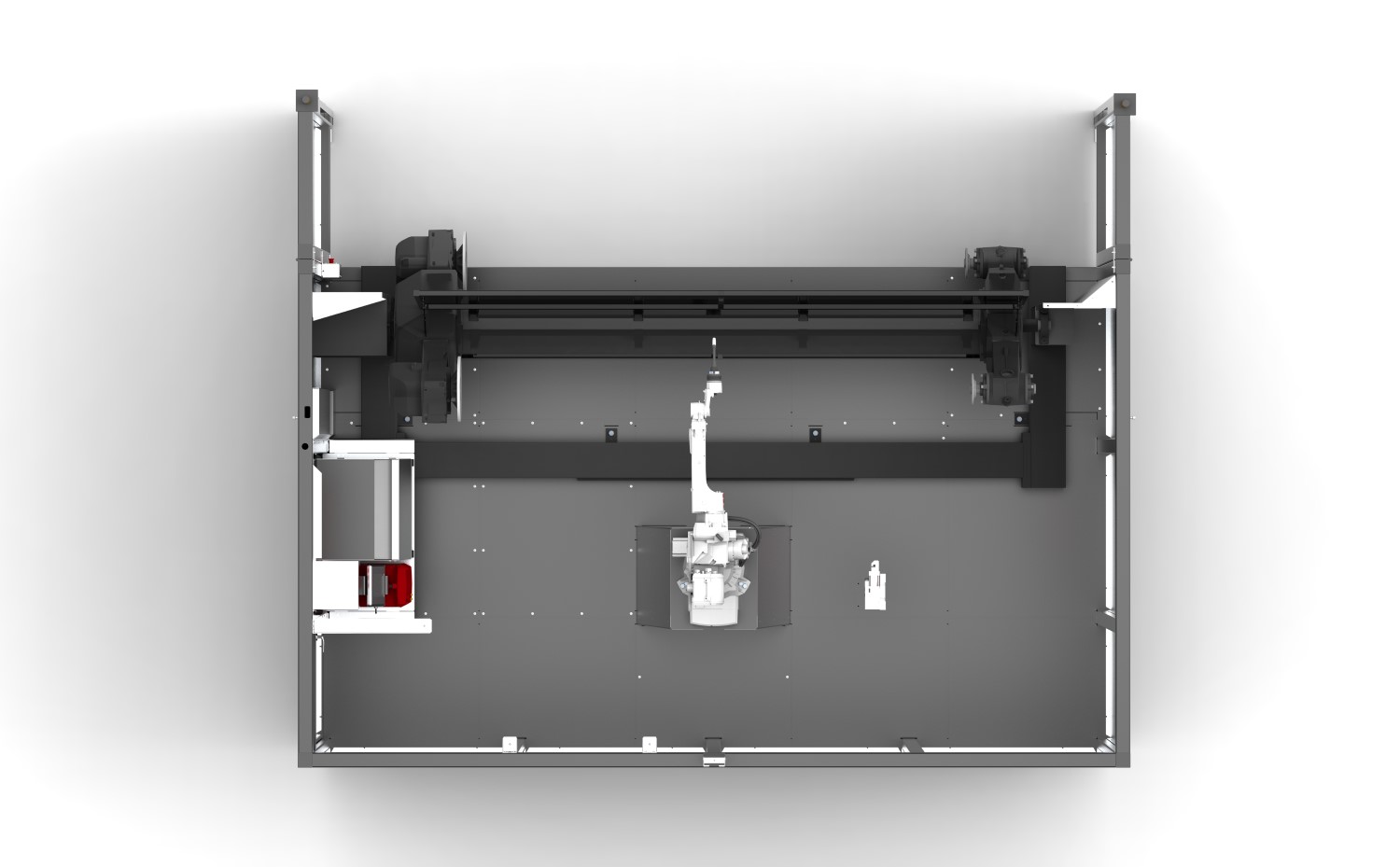

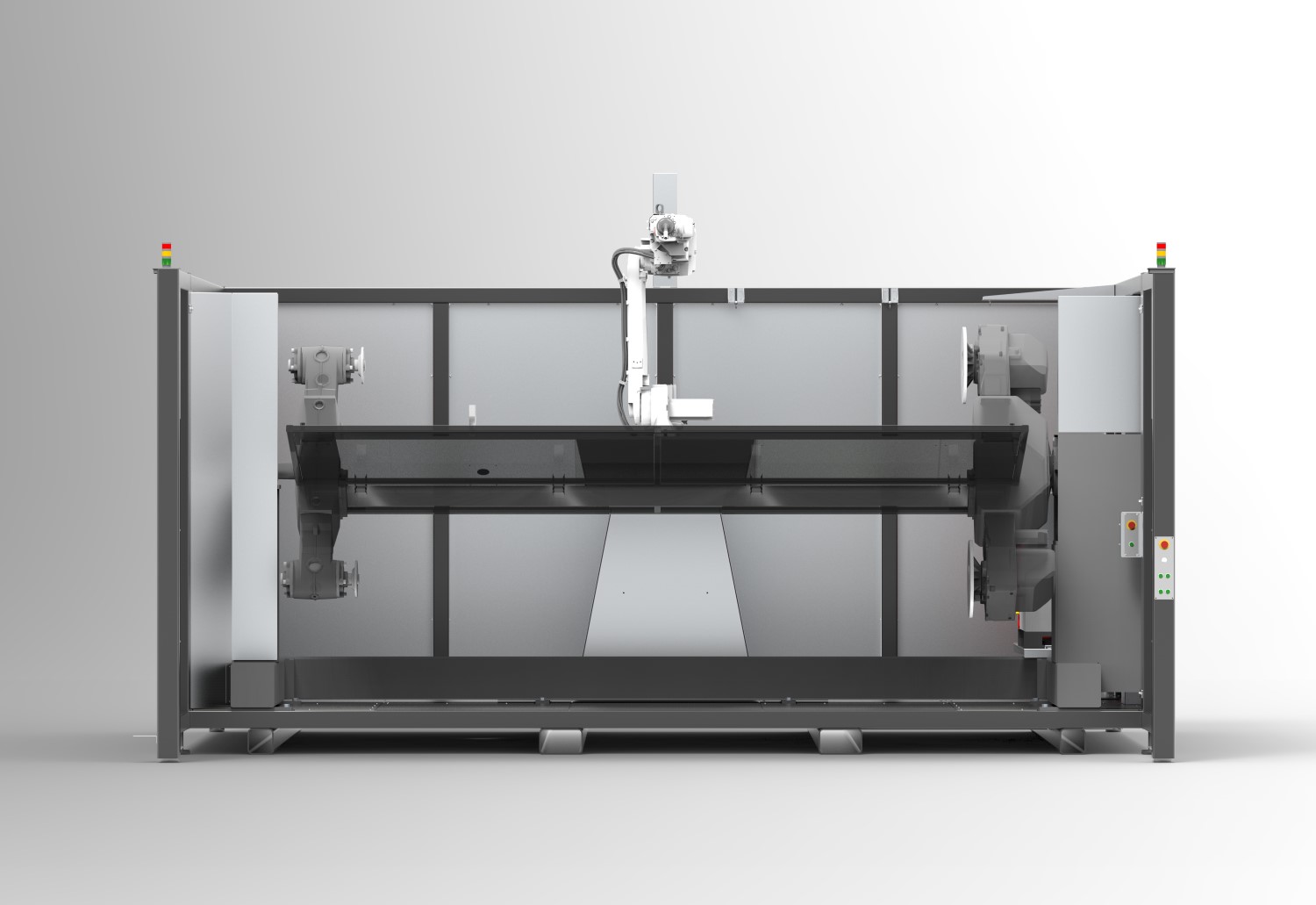

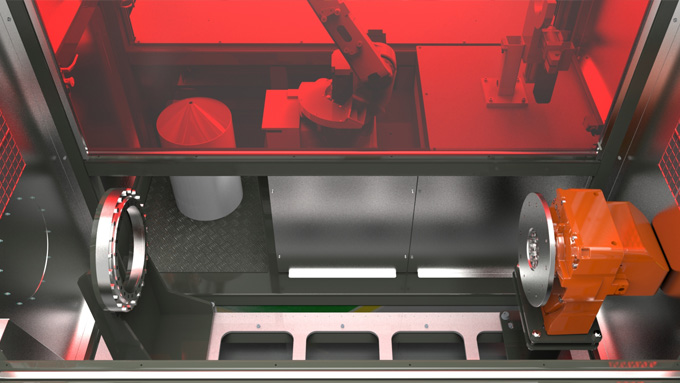

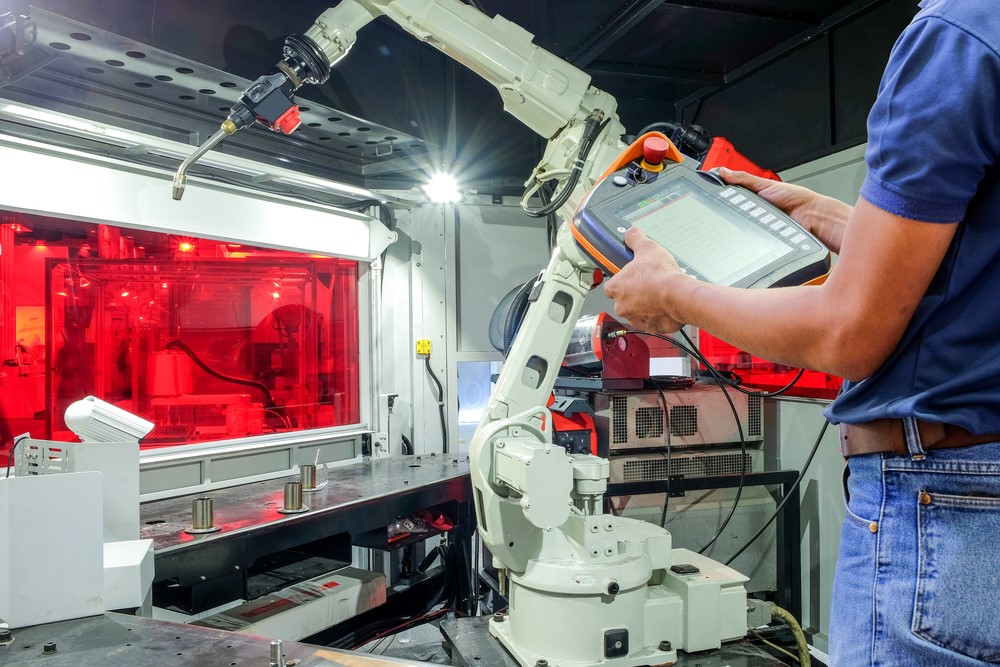

Robotic Weld Cell

The Robotic Weld Cell, also known as MexxWeld, is movable by forklift via its integrated folk tines. Once in place and connected, it is ready for operation. This is within minutes of delivery.

The Robotic Weld Cell has fully enclosed work areas which ensures safety. The internal weld curtains ensure operators are protected from weld arc on the 2nd bay. The doors are opened automatically ensuring maximum production output. The robot is always welding at a high production rate.

The Robotic Weld Cell have several variants of fixed and rotary tables with various configurations of:

- RK-RD-K - Rotary Table (1200mm x 1800mm to 1400mm x 4000mm)

- FX – Large Fixed Table (2100mm x 900mm) and

- RD – Rotary Table (1800mm x 700mm)

KEY FEATURES OF MEXX WELD CELL:

- Rotary axis coordinated with a welding robot

- The system contains dedicated in feed table or cut pipe from 1m-3m

- Notification light tower and alarm to notify the operator of the cell status and material outages.

- Operator interface through Robot Teach Pendant.

- System safety interlocked and guarded as per Australian and New Zealand Standards

- The system contains fixed part loading locations for each of the parts to be welded

- Dedicated trolley with automatic locating points for finished products

Robotic Weld Cell (Video)

Robotic Weld Cell 2600 (RD-RD-K) Slideshow

Robotic Weld Cell 1520 (RD-RD-K) Slideshow

Robotic Weld Cell (FX-RD) Slideshow

Robotic Welding (Concept Image)

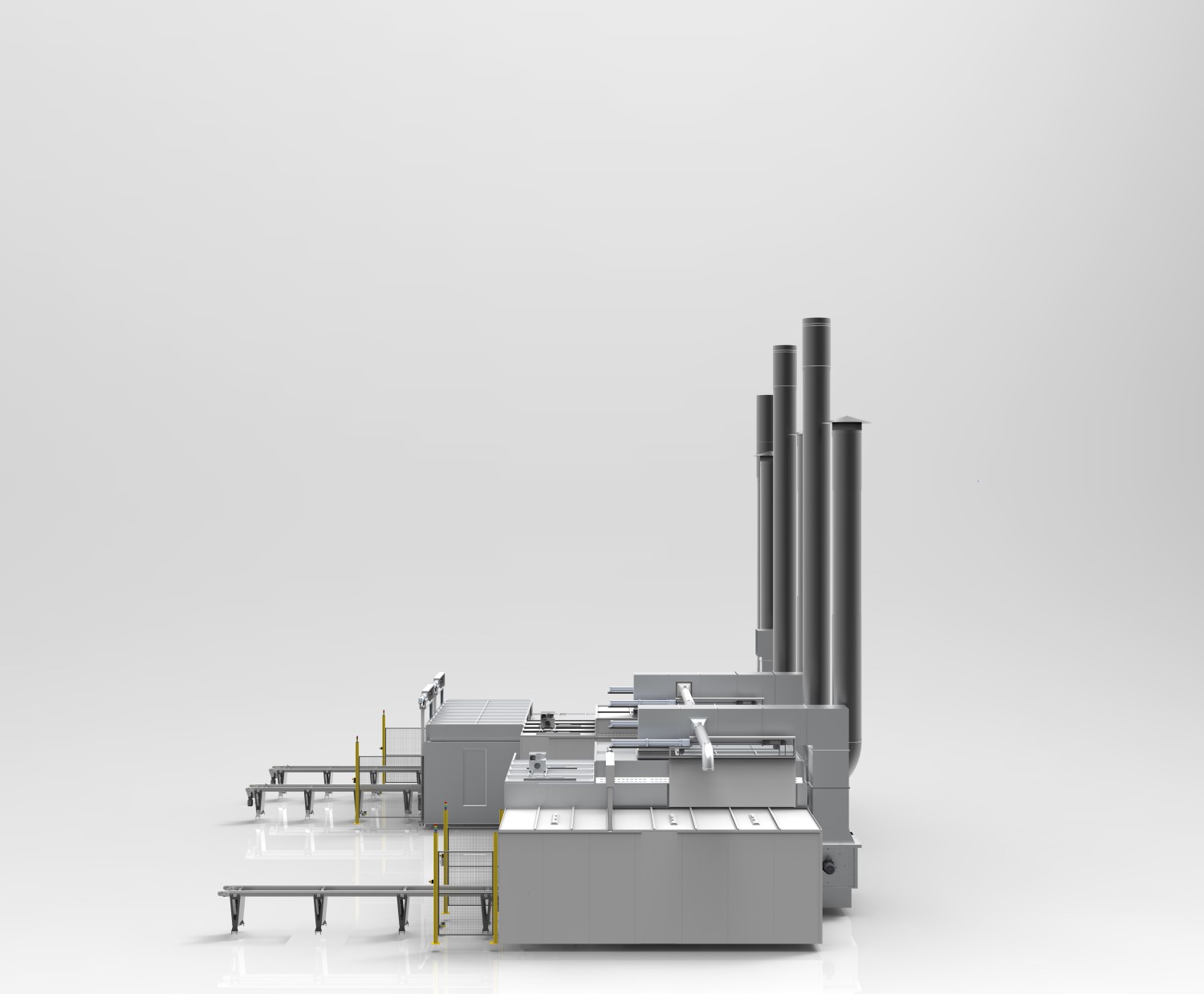

Robotic Painting Booth

The Robotic Paint Booth is a complete painting facility. The robotic system can monitor and control the paint consistency and spray area. A fully automated product handling system manages the product through all painting, handling, and baking process.

A Robotic Painting System is capable of increasing finishing quality, whilst delivering higher production speeds and productivity. It is easy to install and program, and the robots deliver the same high-quality finish time after time without issues such as operators becoming tired or repetitive motion injuries.

KEY FEATURES OF A ROBOTIC PAINT BOOTH SYSTEM

- ABB Robot

- Integrated bake oven

- Custom spray booth with dry medium air filtration

- Temperature controlled paint booth to maintain consistent paint environment all year round

- The integrated automatic indexing system

- Notification light tower and alarm to notify the operator of the cell status and material outages.

- Operator interface through HMI

- System safety interlocked and guarded as per Australian and New Zealand Standards

Robotic Paint Booth (Video)

Robotic Paint Booth Slideshow

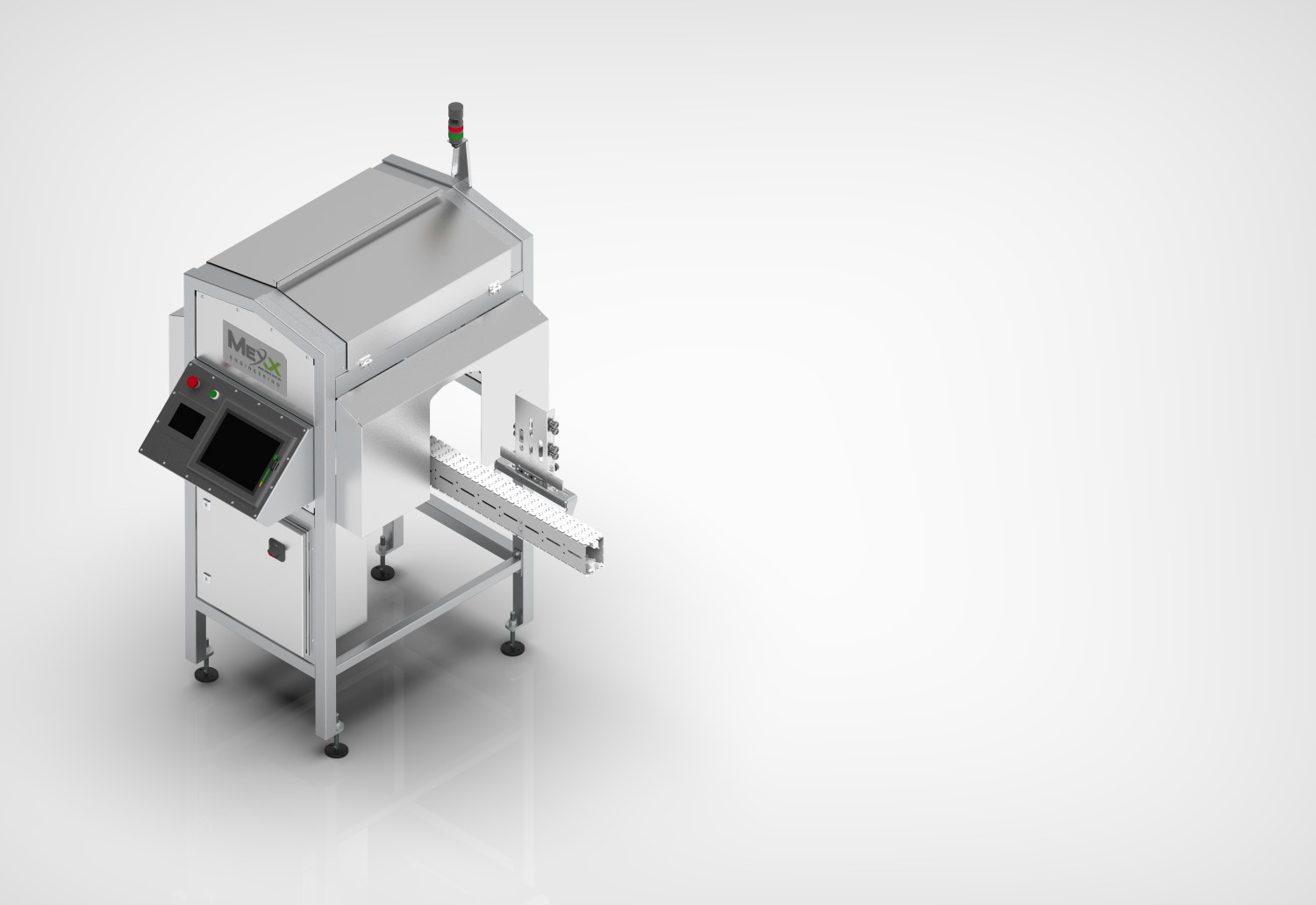

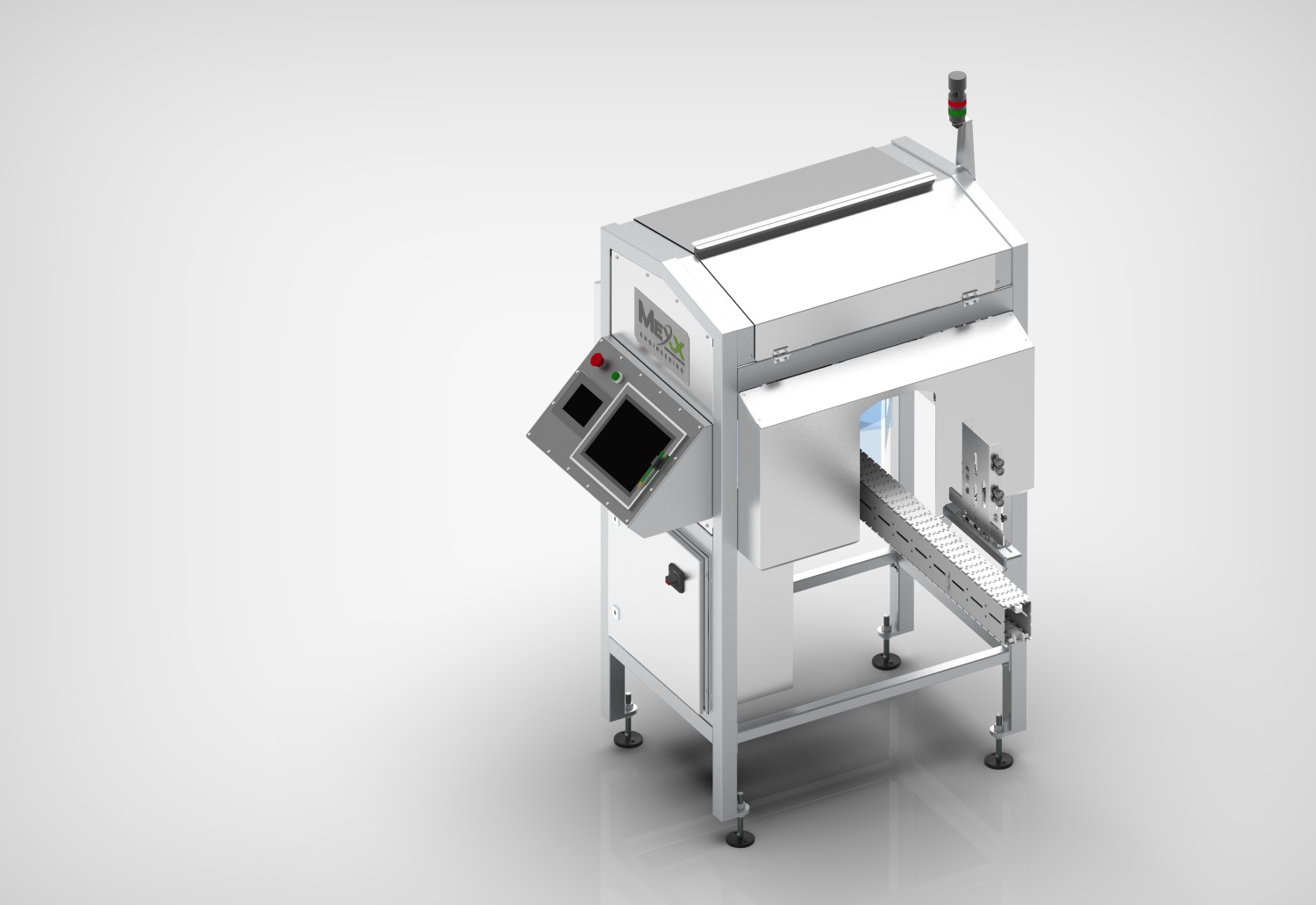

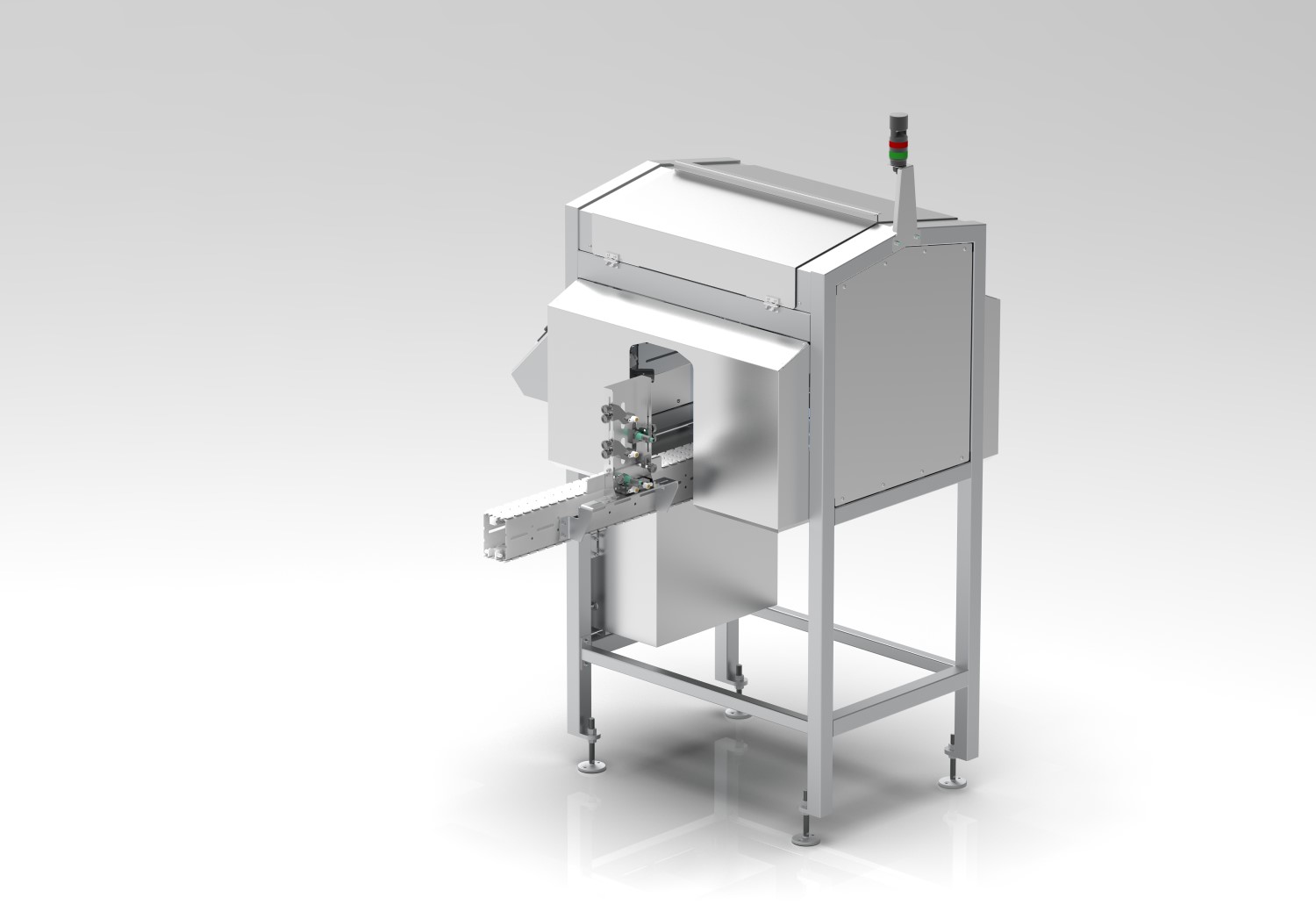

Vision System

The Vision System checks the orientation and quality of a product. It inspects the product for damage and determines how to handle it. A dedicated feeding system that automatically spaces the product can be added as an option.

KEY FEATURES OF THE VISION SYSTEM:

- 5” touch screen for operation and production information

- 20” Display and roller trackball for camera system control and setup

- Light tower for status indication

- PLC Controlled - Independent floor mounted frame for stability

- Central control via HMI

- System safety interlocked and guarded as per Australian and New Zealand Standards

Vision System - Stainless Steel (Slideshow)

The marine industry is currently dependent on experienced workers who face the prospect of long hours and challenging tasks such as welding, cutting, blasting and painting. Unfortunately, the dwindling labour force is unable to cope with the increasing demand. Robots are now filling the labour gaps while sparing humans the most dangerous and thankless repetitive tasks.

Due to the considerable volume of heavy machinery involved with working in the industry, accidents and fatalities are more likely. Of course, businesses have rigorous safety procedures in place, but no matter, there is always going to be hazards and risks. By using robotics, shipyards can protect humans from possibly dangerous situations while improving the quality of throughput.

Mexx Engineering can design and build a machine that can perform:

- material handling

- routing of hull

- spray painting

- welding

Recent movements suggest that the shipbuilding industry is acknowledging robotics as a force of efficiency together with a technique to prevent workers from performing dangerous tasks such as welding.

Welding is one of the main occupations in shipbuilding and is directly related to the cost and quality of products. Automation of the welding process in shipyards is vital to improving productivity, and robots play an important role. Welders frequently operate in tight spaces that are uncomfortable and may require them to change position continually over long distances. Robots carry out repetitive tasks quickly, tirelessly, and accurately.

On the other hand, grit blasting is a dangerous procedure that creates dust clouds and hazardous environments for workers. Some shipyards have implemented the use of ultra-high power water jets via manual blasters for stripping, but the technique has demonstrated to be labour-intensive and incredibly time-consuming. Mexx Engineering can develop a highly flexible robot that can strip using the same method of blasting, but the results now include environmental benefits and worker safety.

BENEFITS OF ROBOTIC PAINTING AND WELDING SYSTEMS

The benefits of integrating robotic painting booth and robotic welding cells within an automated manufacturing process include:

- Increased painting or welding output

- Repeatable finished product

- Less work-related injuries

- Increased reliability, quality and consistency in painted or welded products

- A greater competitive edge through quality guarantee