Meat & Produce

Manufacturers in the meat & produce industry have come to expect the best performing robotic solutions available globally.

Mexx Engineering® is one of the few robotics and automation companies in Australia. We are known for designing and manufacturing complete lines that are built to handle a range of functions from upstream processing, sorting and packing through to the end of line palletisation.

Mexx Engineering® can streamline the meat & produce industry using innovative and versatile systems such as:

The implementation of robotic automation within the meet & produce industry offers incredible potential for improved safety, quality and productivity by enhancing process monitoring and control.

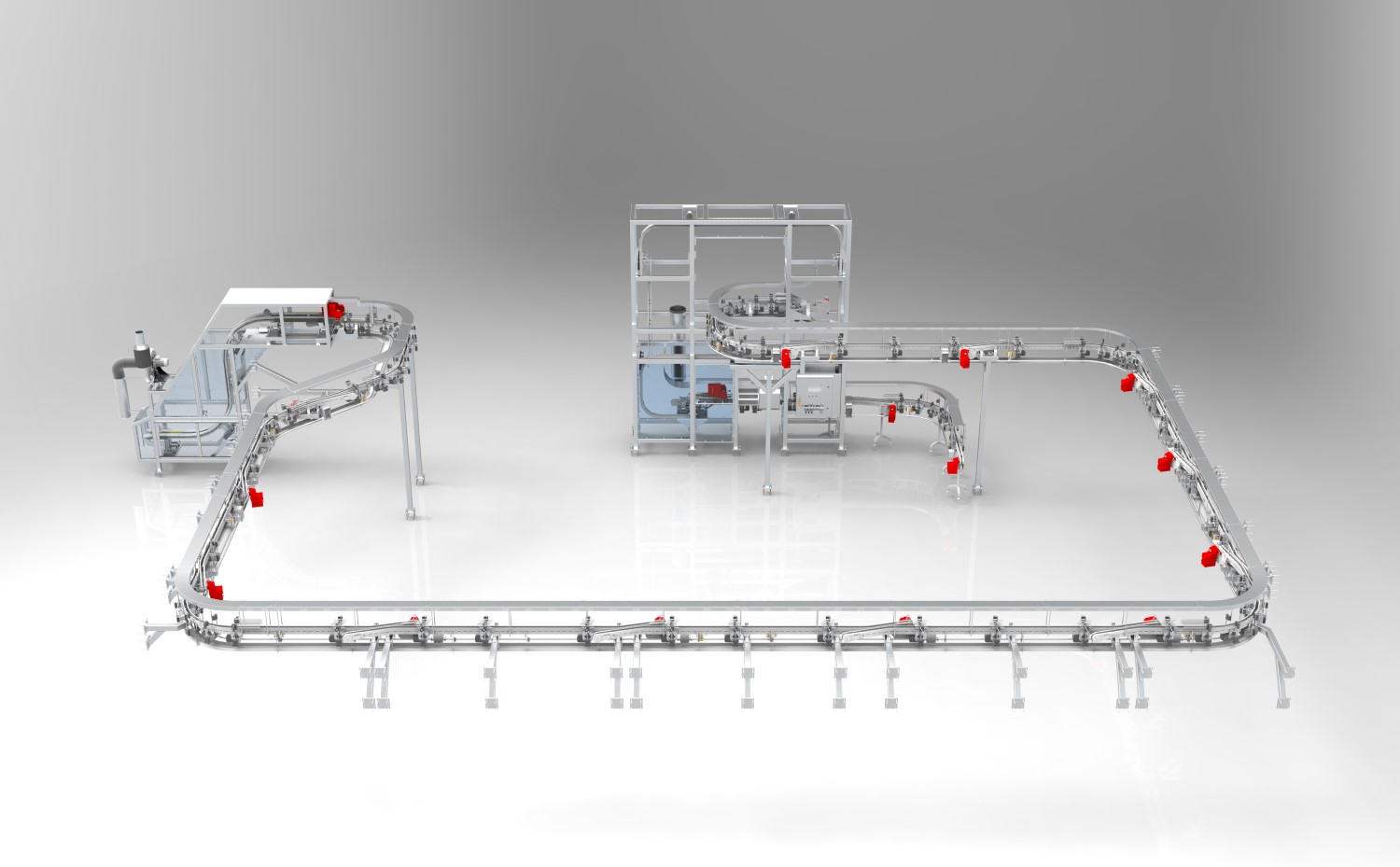

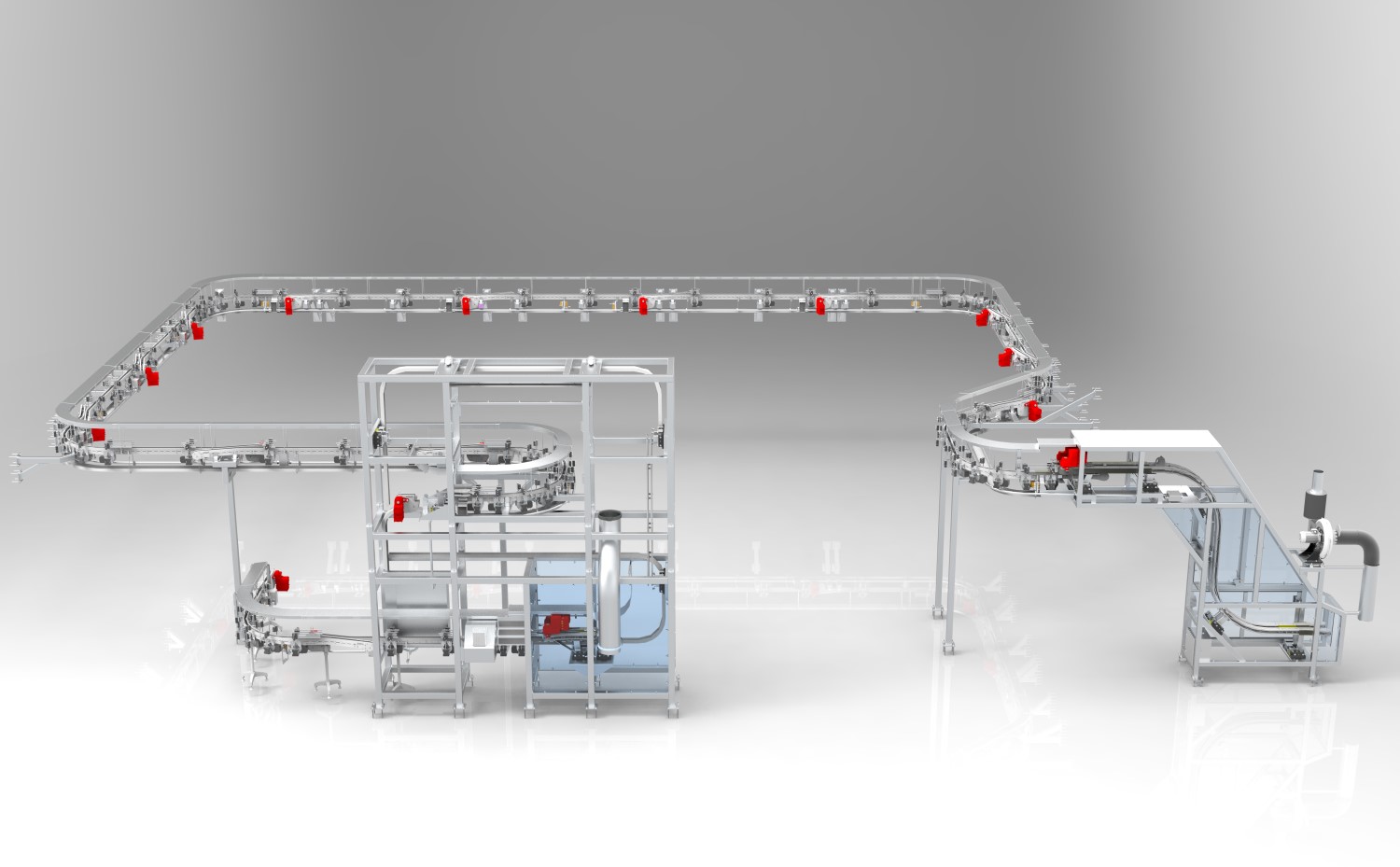

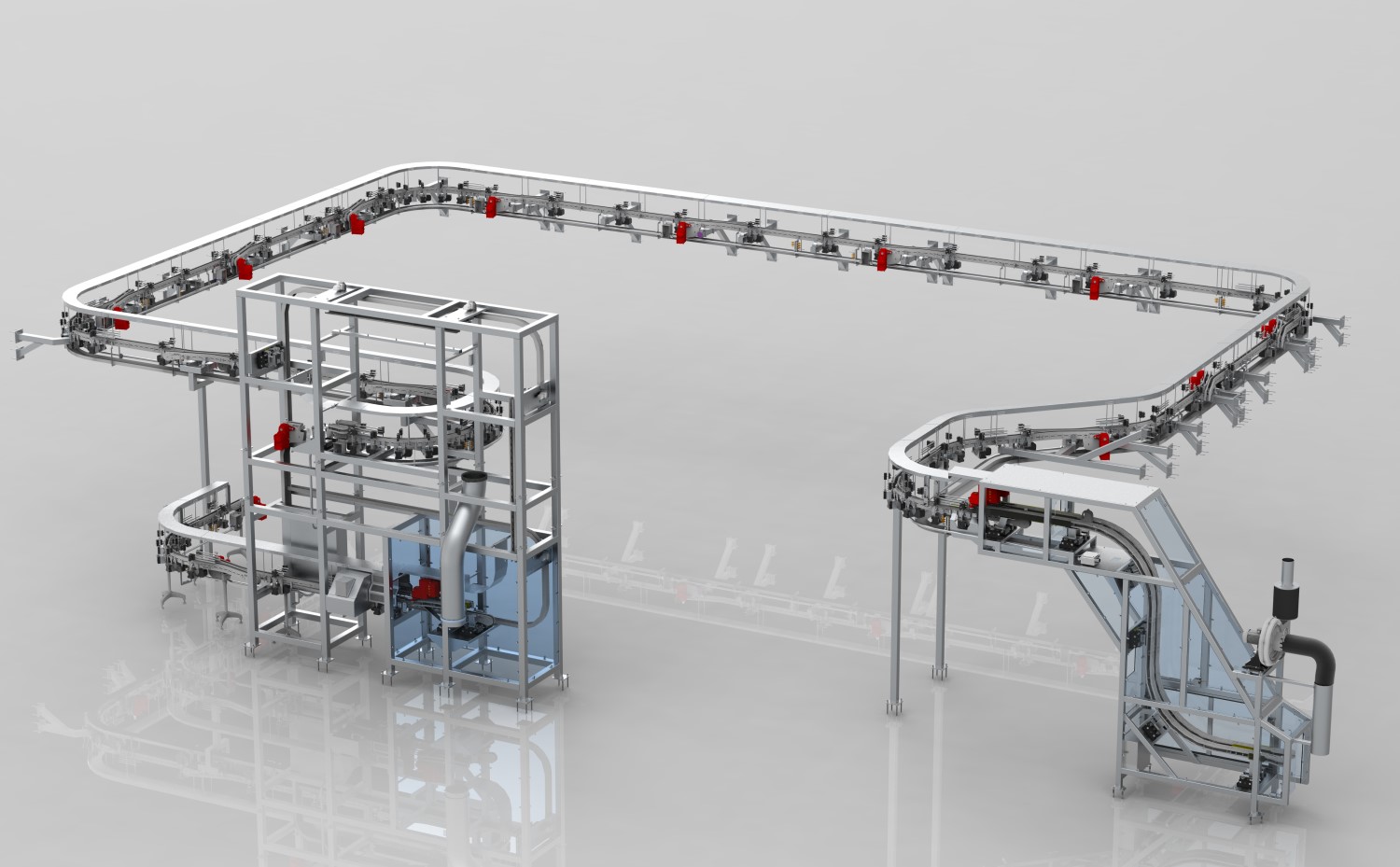

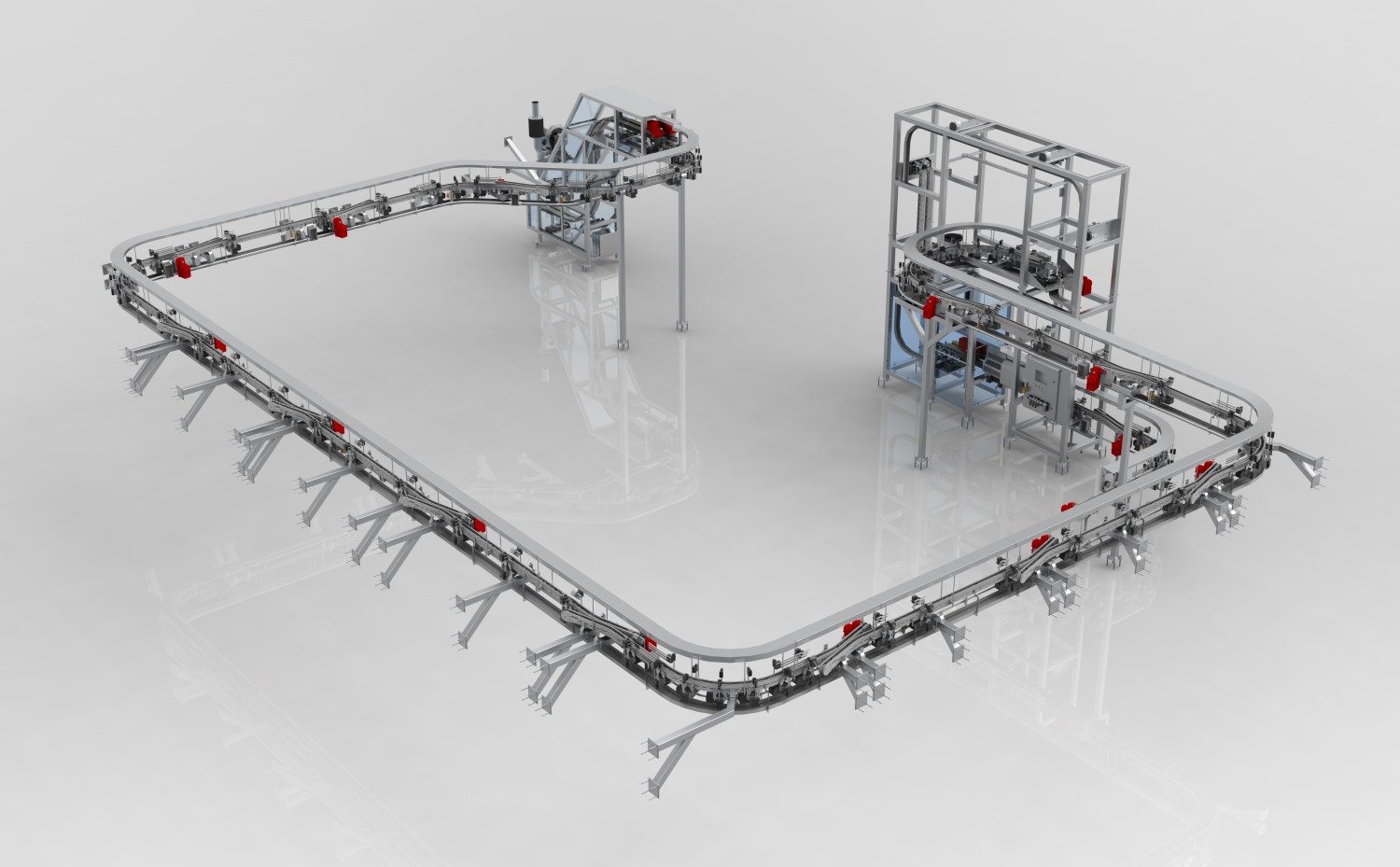

Conveyor System

The Conveyor System controls product delivery from point A to point B with the use of various conveyor chain materials. Its guide rail system is fully adjustable to ensure continuous movement of the product around a curve.

KEY FEATURES OF THE CONVEYOR SYSTEM:

- Aluminium or Stainless conveyor system

- Includes automatic self-centring guide rail adjusters

- Integrated transfers from upstream conveyors

- Integrated transfers to downstream conveyors

- High-speed with virtually no back-pressure and product gaps

- Accumulation system

- Full system control

- System safety interlocked and guarded as per Australian and New Zealand Standards

Conveyor System

Conveyor System (Slideshow)

Various Conveyor Types (Slideshow)

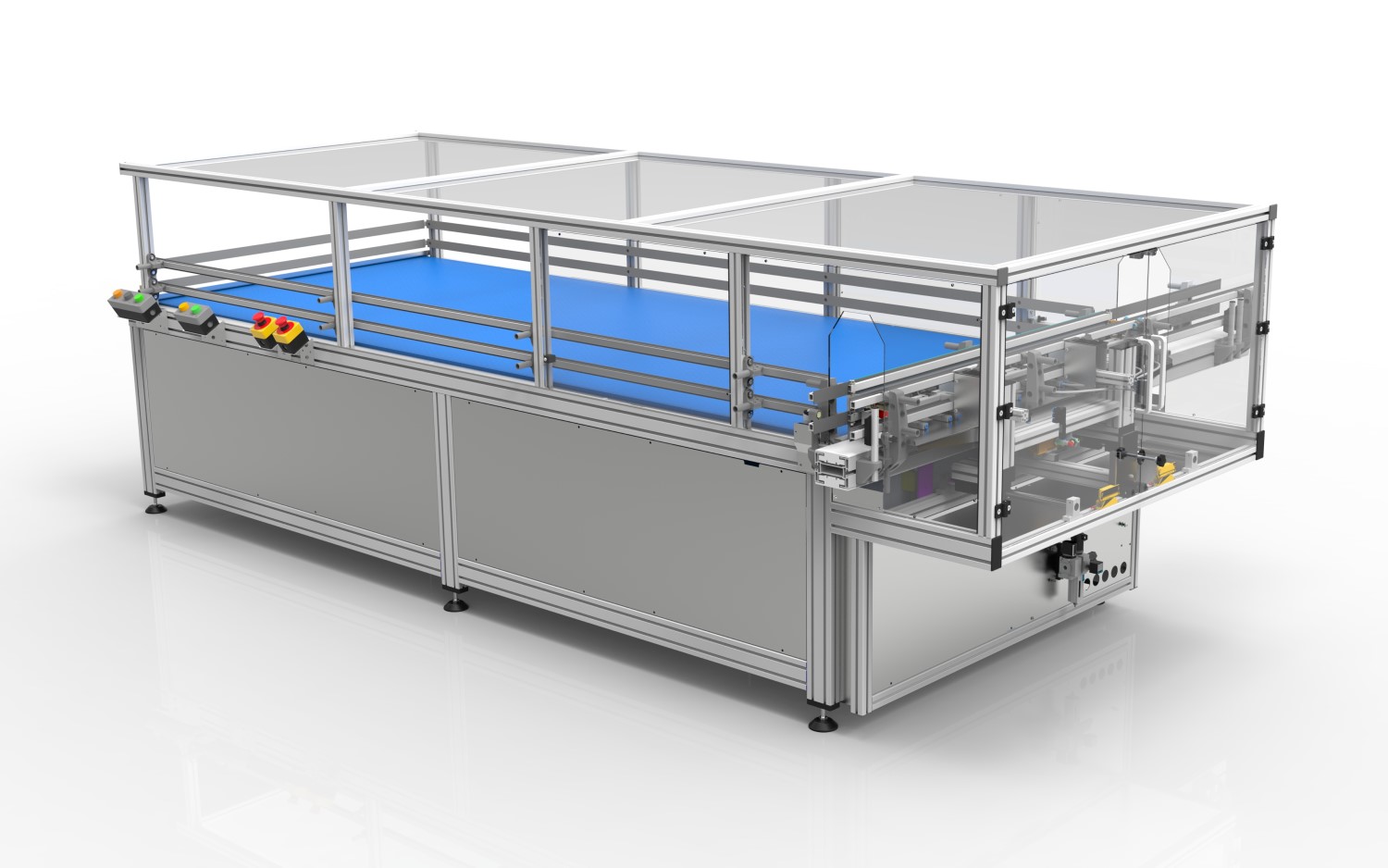

Vision System

The Vision System checks the orientation and quality of a product. It inspects the product for damage and determines how to handle it. A dedicated feeding system that automatically spaces the product can be added as an option.

KEY FEATURES OF THE VISION SYSTEM:

- 5” touch screen for operation and production information

- 20” Display and roller trackball for camera system control and setup

- Light tower for status indication

- Eject product using air blast

- PLC Controlled - Independent floor mounted frame for stability

- Central control via HMI

- System safety interlocked and guarded as per Australian and New Zealand Standards

Vision System - Aluminium

Vision System - Stainless Steel

Custom Design & Automation

Automation is the new edge in farming, both in Australia and overseas, and it is not just in response to a diminishing number of farmers or an exploding escalation in population.

The growing global community and swinging trade guidelines affect the pricing, supply chain, and distribution of food products. In the meantime, consumers first choices, especially in western countries, are changing more toward organic and sustainably produced foods and products that require more consideration, data, and labour.

With the demand for produce and meat at a higher regard than ever before, businesses are converting to automation to help speed up their applications. There is an abundance of reasons that automation makes sense for the world of agriculture. With benefits varying from economic to environmental, implementing automated systems in Australian farms could advance the industry forward in an awe-inspiring way.

Egg Packaging Machine (Concept Image)

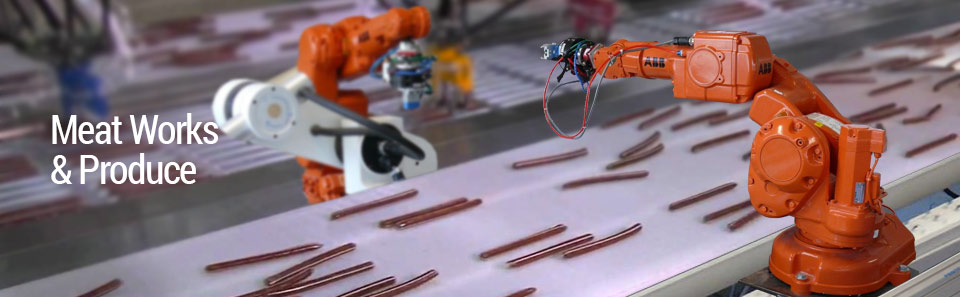

Meat Works

Manufacturers achieve many advantages by automating their meat processing treatments, including reduced cycle times and increased quantity. This means that meat is delivered to the customer earlier and faster, which lessons spoilage and provides it with the best shelf life possible. Also, employees are away from the sharp cutting tools that may have once caused personal injuries or harm in the past, improving the safety of the production line. Meat cutting has always been one of the most highly hazardous operations in food manufacturing, for both employee and product safety. With the application of meat processing robotic automation, contrasting to human involvement, there is a massive decline in the potential for product contamination. Hence, the meat is safer for human ingestion.

Efficiency is a crucial emphasis on meat and poultry manufacturers. The capability to derive the utmost amount of meat from a carcass in the fastest time is the best formula for making substantial revenues. Meat processing robotic automation must be able to withstand moisture, rust and any other outside elements that could corrode the metal.

Mexx Engineering® can assist in providing solutions for:

- accurate portioning and precision cutting

- efficient loading and unloading

- effective wrapping and high-speed packing

Conveyor System in a meat packaging plant (Concept Image)

Produce

The ever increasing and fluctuating demand for produce challenges the agriculture industry. Tackling labour shortages and increasing costs for farm work is becoming an issue. Several farmers are facing a predicament between wanting to produce more, higher-quality crops and finding the personnel to plant, maintain, and harvest those crops. Although generating more food is extremely important, there is also surmounting pressure on farmers to make their methods greener and more environmentally friendly. In doing so, farmers must use water efficiently, reduce or cut out the number of insecticides that are used and focus on sustainability as well as producing good quality food. Using autonomous vehicles and robots can be a critical factor in achieving this goal.

Mexx Engineering® can provide technological advantage by designing and manufacturing automated solutions such as robotic machines that are well suited for growing, harvesting, packing, processing, and warehousing operations for produce and floral businesses.

Apple Cleaning Machine (Concept Image)