Automated Concrete Test Lab

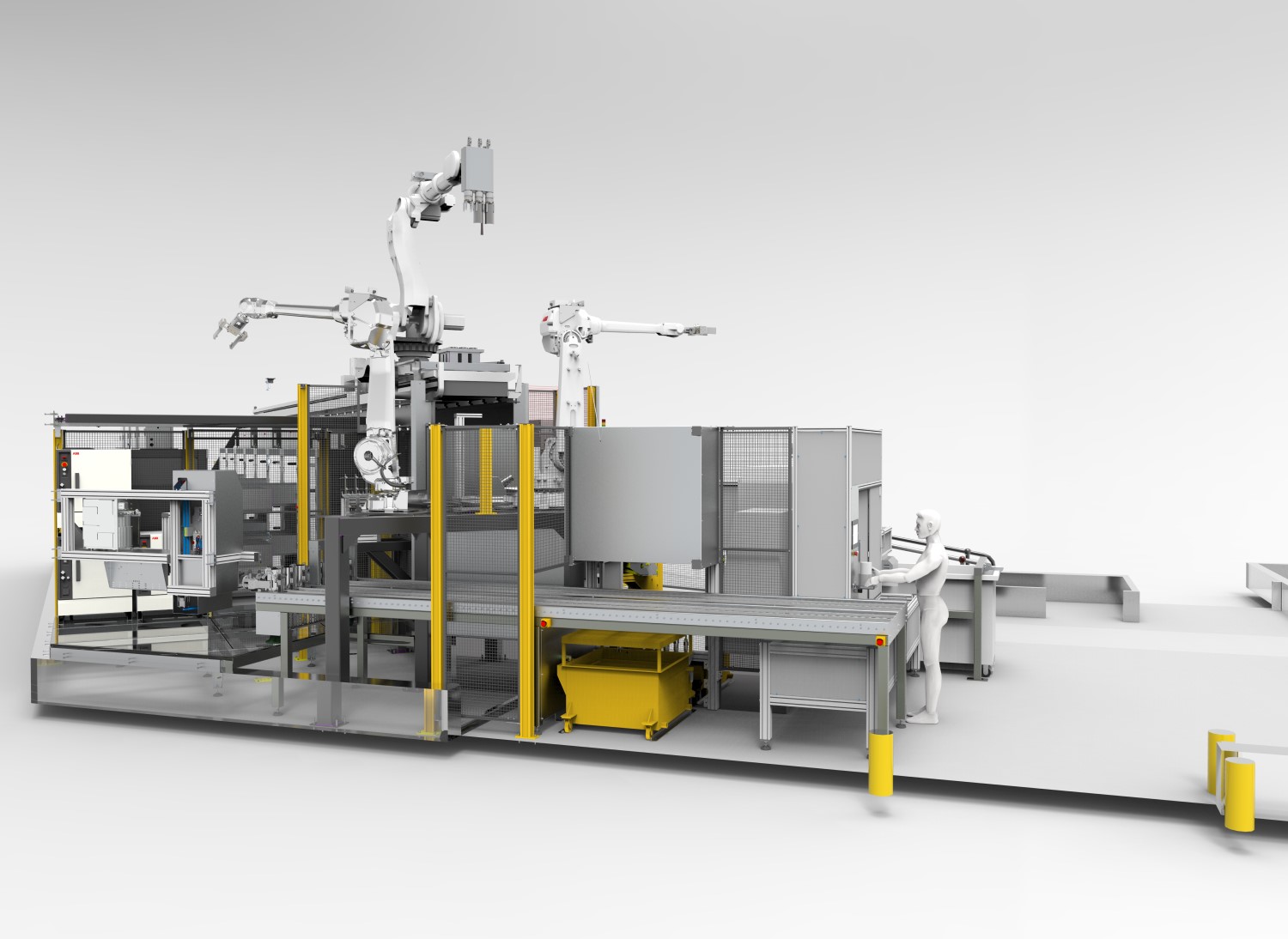

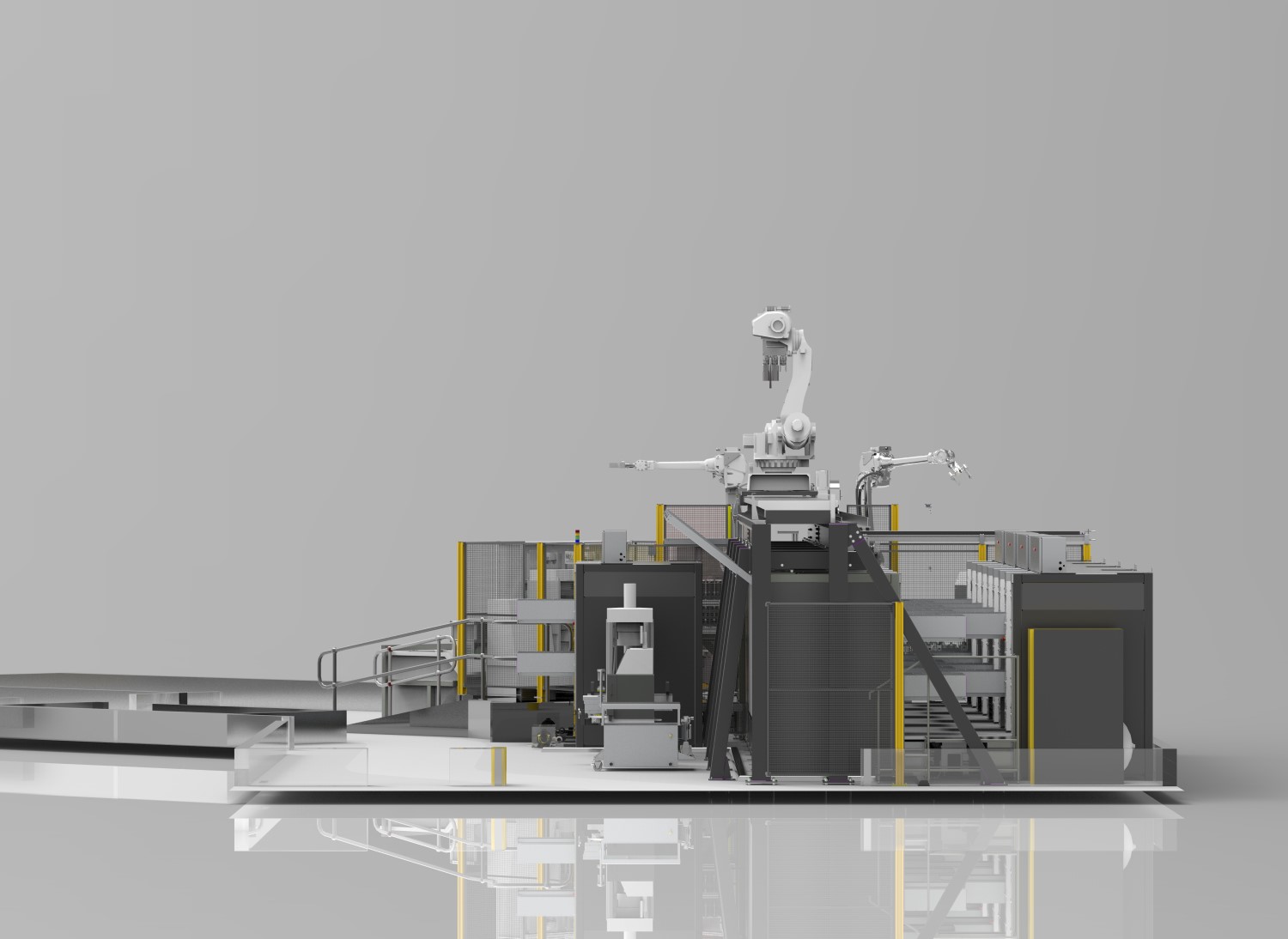

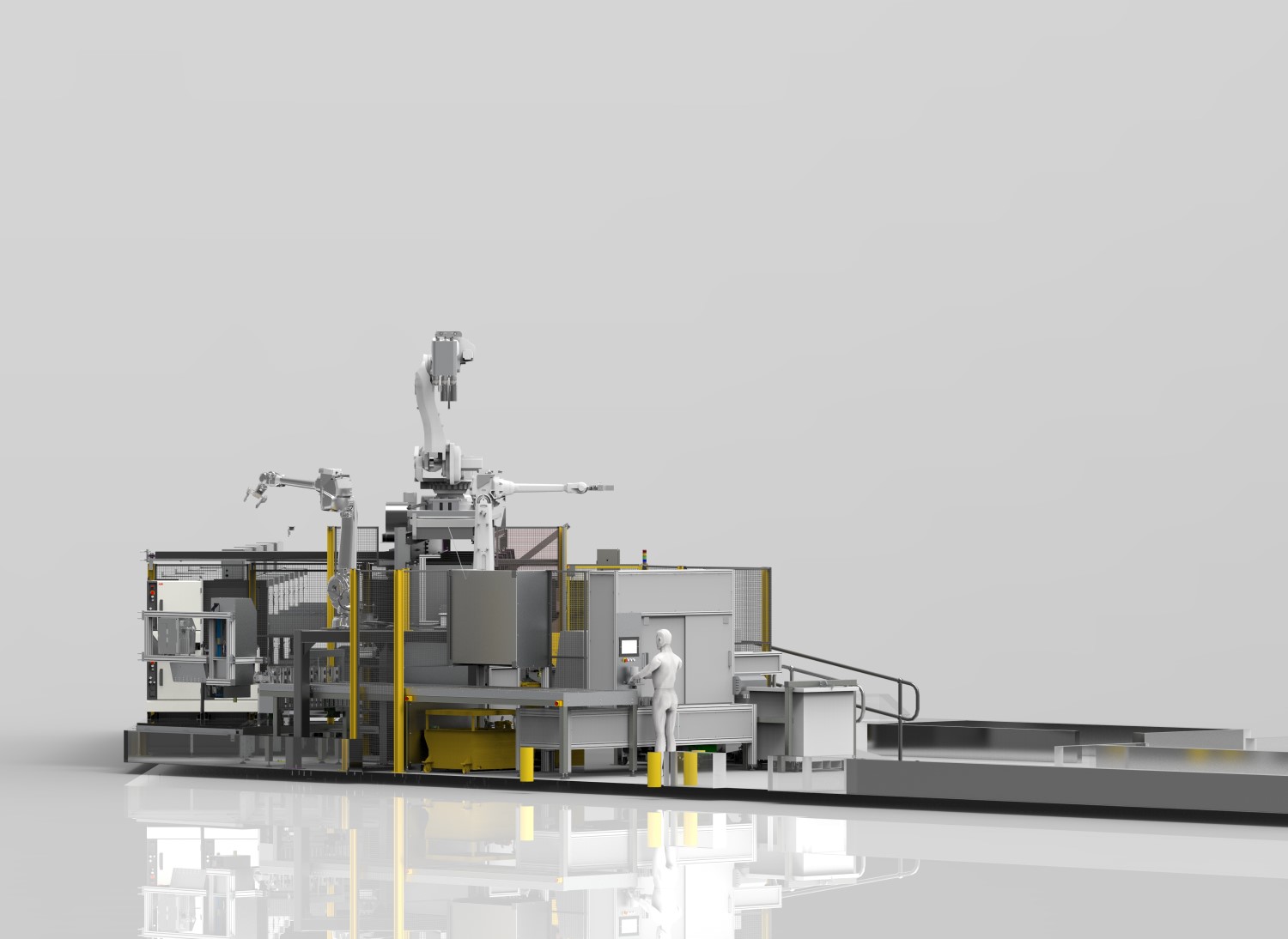

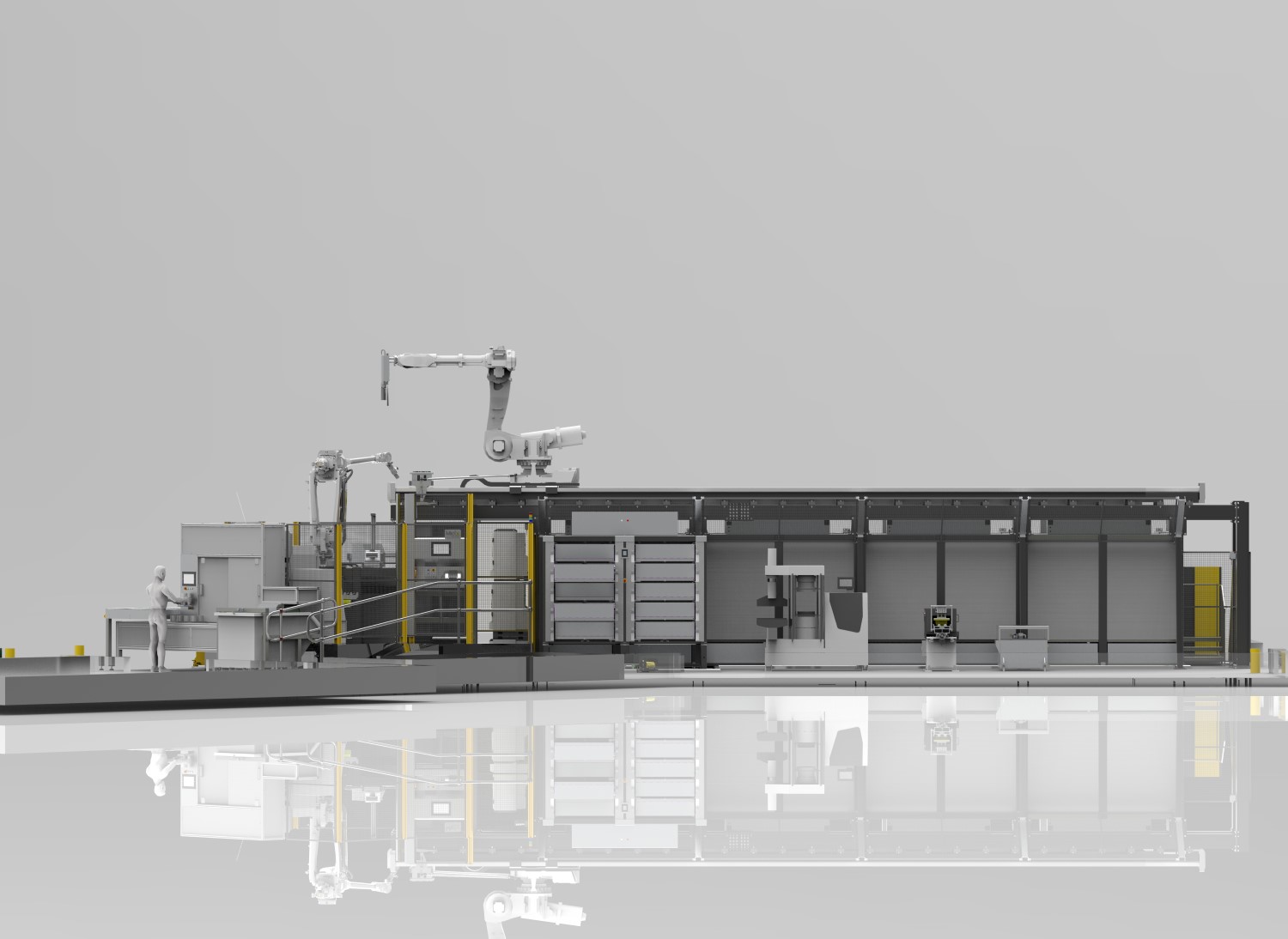

The Automated Concrete Test Lab serves as a storage and lab testing facility that consists of 3 main processing areas; the incoming cores, the limewater storage and handling, and the core testing.

Automated Concrete Test Lab

KEY FEATURES OF THE AUTOMATED CONCRETE TEST LAB:

- 2 ABB Robots for core handling

- Dedicated de-mould and clean station/machine

- Infeed conveyor system for moulded cores

- Outfeed conveyor system for returning demoulded moulds

- Control the interaction of the various system components.

- HMI interface communicates data of each core at all stages of transport and testing

- Automation of grinding machine and location of the water tank

- Automation of Compression Testing Machine

- System safety interlocked and guarded as per Australian and New Zealand Standards

HOW DOES IT WORK?

The primary function of this system is mange the overall operation of the system including:

- The processing of the samples by recording data at various identification points and processing points.

- Managing safety access to various parts of the system

- Control the interaction of the various system components.

- HMI interface communicates data of each core at all stages of transport and testing

APPLICATIONS FOR THE AUTOMATED CONCRETE TEST LAB:

The integration of high-end automated concrete test lab can increase productivity or efficiency within the construction industry.

TURNKEY SYSTEM

This type of setup will require a vision system to detect the barcode attached to each test sample. This setup is called a turnkey system. The automated concrete test lab is one-of-the-kind. It is smart and programmable.

As a turnkey system, the automated concrete test lab is a fully automated system where the following components are purposely added to create a sophisticated machine:

DESIGN AND BUILD PERIOD

As a stand-alone machine or EOM product, it may take around 25-weeks from purchase order to delivery. On the other hand, a custom-made turnkey system can take longer depending on the customer's requests and specifications.

SERVICE MAINTENANCE

Service maintenance is any work necessary to keep all customer facilities in good repair and operating condition. It includes maintaining and repairing essential components of a machine. This excludes explicitly new work and alterations such as:

- manufacturing and modifying machines and complete lines

- providing decorative treatments

- modifying vision systems

- attaching or extending items to the machine.

WARRANTY

All of Mexx Engineering® machines and turnkey systems come with a minimum of one year warranty on workmanship and materials.

Each system developed by Mexx Engineering® is a seamless automated machine that minimises environmental impact and maximises performance while ensuring the safety of its operator.

For more information, please contact 07 5571 5733 and choose option 1 for sales, to discuss the best combination of equipment and system maintenance to suit your application.